Your Cart is Empty

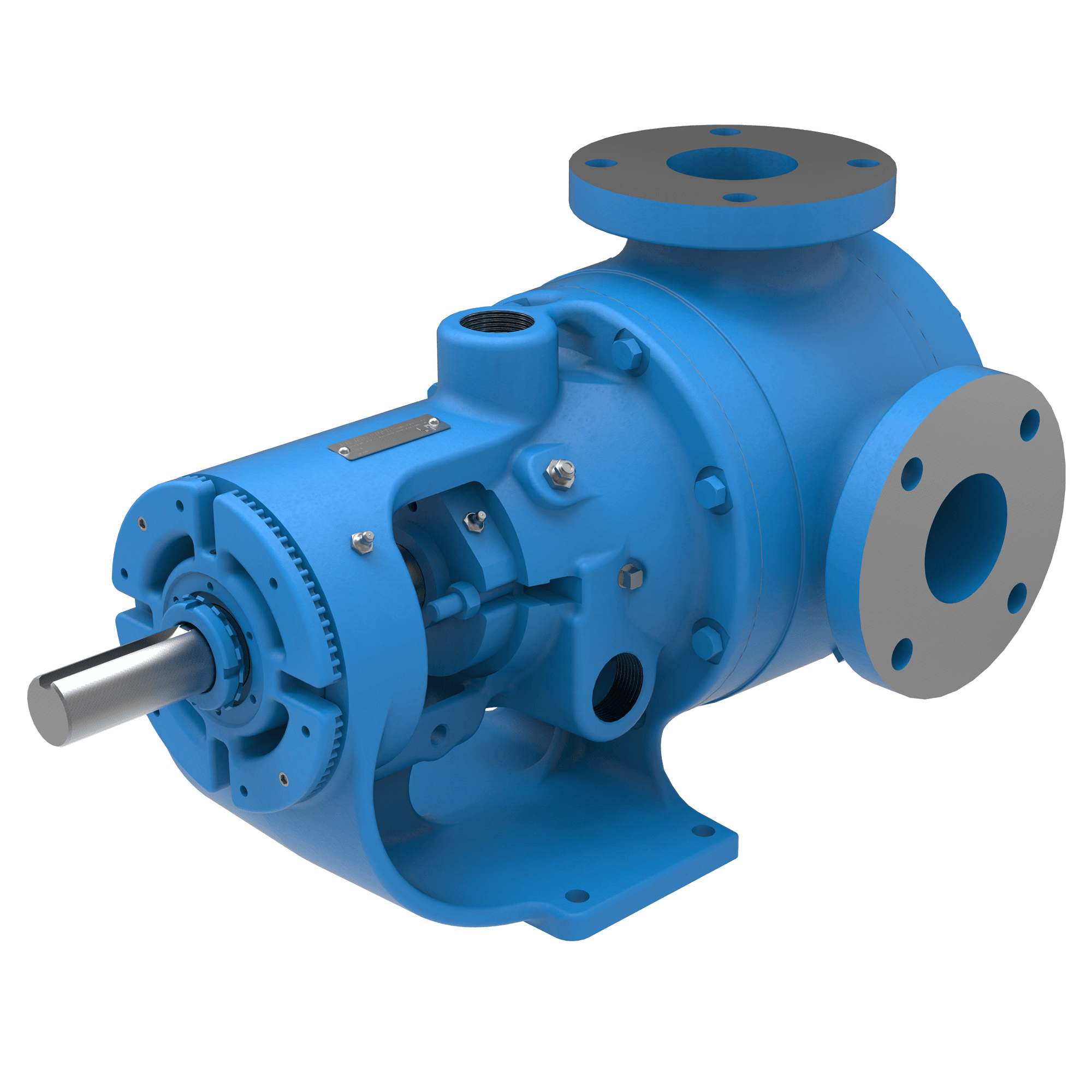

Viking Pump - Chocolate Pump

Viking's 1224A-CHC pump is designed with chocolate in mind. With a Double O-Ring seal, this pump is instrumental in leak-free pumping. Some other applications include Cocoa Liquor, all Chocolates and Pastes (CHC1 models) and Cocoa Butter, Oils, and Lecithin (CHC2 Models).

- Capacity: 1 – 400GPM

- Viscosity: 25,000 – 900,000

- Pressure to 200PSI

- Temperature to 225F

-

This product price is available on request only

Product details

Viking Pump has been a trusted partner in reliability with chocolate and confectionery processors around the world for more than a century. As the world’s leading positive displacement process pump manufacturer, solving difficult liquid transfer problems is what we do. And it doesn’t get more difficult than chocolate, so you can rely on Viking’s experience and expertise.

-

- Low shear design protects delicate chocolate suspensions

- Hard materials provide long life on abrasive liquors and chocolates

- Internal gear principle handles viscosities ranging from thin cocoa butter to thick peanut butter

- Rotatable casing can locate ports in any of 8 positions for easy piping connections

- Simple, in-house maintenance

- Stocking distributors worldwide provide local service and support

- In-house research lab for prompt liquid performance and endurance testing

- Vertically integrated product process, from raw materials to finished product,

meets ISO 9001:2015 quality standards

Viking Pump 1224A-CHC Series™ pumps are designed specifically for handling chocolate and related confectionery processes. These pumps are suitable for low hazard foods like chocolate according to each facility’s HACCP plan. They are not a hygienic design according to 3A or FDA, and are not suitable for services requiring CIP or COP.

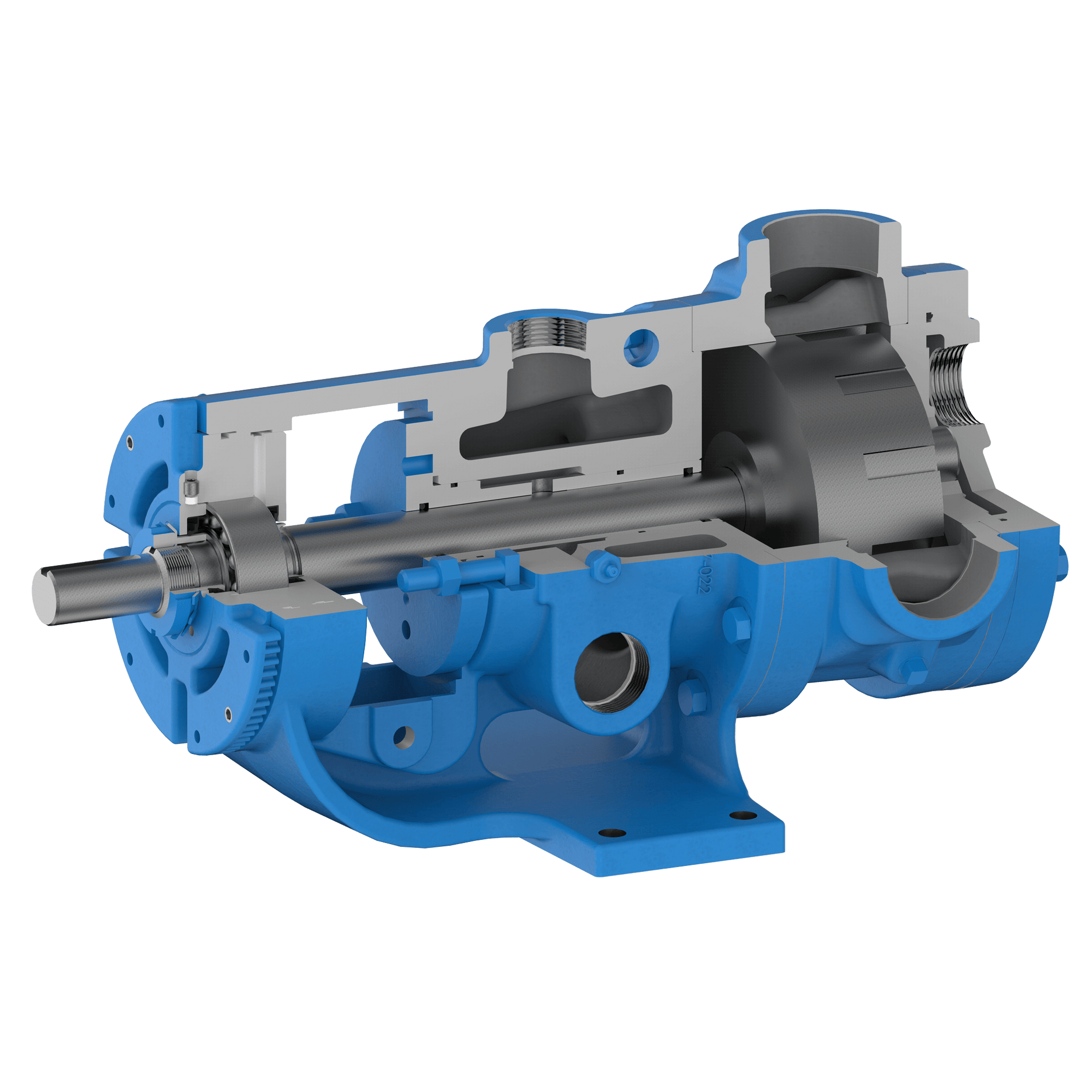

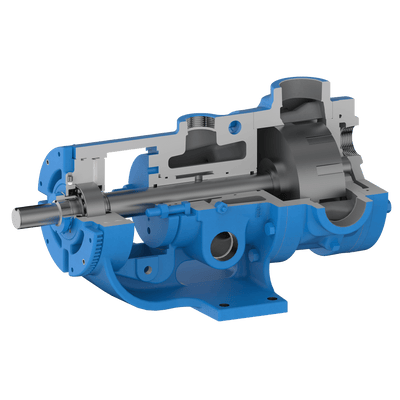

RELIABILITY - 1224A-CHC1 models for chocolate liquids minimize frictional heat at bushings and prevent solids buildup that can cause seizing. The O-Pro™ Barrier Seal is lubricated with clean food-grade grease instead of chocolate, and keeps chocolate out of the bracket while providing superior shaft support; the extra-clearance idler gear and bushing are drilled to ensure flow between the bushing and pin to reduce heat; and flush and suckback grooves on the casing create flow behind the rotor to eliminate buildup. High-strength steel or ductile iron rotors handle high viscosities, and hardened iron bushings and hardened steel shafts minimize wear. There’s no packing to adjust, which eliminates common overtightening problems.

LESS PUMP & PART VARIATION The 1224A-CHC2 models for non-chocolate liquids are identical to CHC1, except the casing does not have flush and suckback grooves, for higher efficiency on thin liquids like cocoa butter. This reduces pump and spare part variation, and enables easy conversion from CHC1 to CHC2 and vice versa. Seal kits enable low-cost conversion of existing Viking Universal Seal pumps to the O-Pro™ Barrier Seal.

FOOD SAFETY - EC1935 COMPLIANT The pumps are constructed of food grade materials and carry the EC1935 mark to limit leaching of harmful substances into food, and are suitable for use on low hazard foods like chocolate, according to your HACCP plan.

SIMPLE MAINTENANCE O-rings are replaceable with the pump in-place, when configured with spacer couplings allow space to remove the O-Pro™ Barrier Seal. Jack screws in seal kits allow easy O-Pro™ Barrier Seal removal. Proven O-ring sealing technology means low cost seal replacement. Recommended re-greasing interval is every 500 hours of operation.

O-PRO™ BARRIER SEAL BUSHING The O-Pro™ Barrier Seal combines a bracket bushing and seal gland, with double O-ring seals, to seal chocolate out of the bracket and food grade grease in to provide lubrication for the bracket bushing

DRILLED IDLER The idler gear features a hardened iron bushing, extra clearances, and holes drilled through to ensure flow between the idler and pin, preventing chocolate from burning

NAMEPLATE - EC1935 COMPLIANT Pump nameplate features the EC1935 compliant cup and fork symbol to provide assurance of food-compatible materials of construction

-

Materials of Construction

- Casing, Head, Bracket & Idler: Cast Iron (except H/HL idlers powdered metal, Q idler hardened steel)

- Rotor: Steel (Sizes H, HL, K, LQ, LL, Q); Ductile Iron (Sizes KK, LS, QS)

- Shaft: Hardened Steel

- Bracket & Idler Bushings: Hardened cast iron

- Seals: Food grade gaskets and FDA FKM O-rings

- Lubricants: Food grade grease

- Jacketing: Jacketed heads and brackets standard to enable melting chocolate before startup

Performance

- Maximum Chocolate Temperature: 225°F / 107°C

- Maximum Chocolate Differential Pressure: 200 PSI / 14 BAR

CHC1 Model for Cocoa Liquor, All Chocolates, Pastes (≈5,000 to 200,000 cPs) Max Speed RPM Ports CHC2 Model for Cocoa Butter, Oils, Lecithin (≈1 to 5,000 cPs) Max Speed RPM Size Type Location H1224A-CHC1 280 1.5" NPT 90o H1224A-CHC2 1000 H1224A-CHC1 280 2" Flange 90o H1224A-CHC2 1000 HL1224A-CHC1 280 1.5" NPT 90o HL1224A-CHC2 1000 HL1224A-CHC1 280 2" Flange 90o HL1224A-CHC2 1000 K1224A-CHC1 190 2" NPT 90o K1224A-CHC2 780 K1224A-CHC1 190 2"/3" Flange 90o K1224A-CHC2 780 KK1224A-CHC1 190 2" NPT 90o KK1224A-CHC2 780 KK1224A-CHC1 190 2"/3" Flange 90o KK1224A-CHC2 780 LQ1224A-CHC1 125 3"/4" Flange 90o LQ1224-CHC2 640 LL1224A-CHC1 125 3"/4" Flange 90o LL1224A-CHC2 520 LS1224A-CHC1 125 3"/4" Flange 90o LS1224A-CHC2 640 Q1224A-CHC1 100 4" Flange 90o Q1224A-CHC2 470 QS1224A-CHC1 100 *4"/**6" Flange *90o/**180o QS1224A-CHC2 470 -

- Description

- Low shear design protects delicate chocolate suspensions

- Hard materials provide long life on abrasive liquors and chocolates

- Internal gear principle handles viscosities ranging from thin cocoa butter to thick peanut butter

- Rotatable casing can locate ports in any of 8 positions for easy piping connections

- Simple, in-house maintenance

- Stocking distributors worldwide provide local service and support

- In-house research lab for prompt liquid performance and endurance testing

- Vertically integrated product process, from raw materials to finished product,

meets ISO 9001:2015 quality standards

Viking Pump 1224A-CHC Series™ pumps are designed specifically for handling chocolate and related confectionery processes. These pumps are suitable for low hazard foods like chocolate according to each facility’s HACCP plan. They are not a hygienic design according to 3A or FDA, and are not suitable for services requiring CIP or COP.

RELIABILITY - 1224A-CHC1 models for chocolate liquids minimize frictional heat at bushings and prevent solids buildup that can cause seizing. The O-Pro™ Barrier Seal is lubricated with clean food-grade grease instead of chocolate, and keeps chocolate out of the bracket while providing superior shaft support; the extra-clearance idler gear and bushing are drilled to ensure flow between the bushing and pin to reduce heat; and flush and suckback grooves on the casing create flow behind the rotor to eliminate buildup. High-strength steel or ductile iron rotors handle high viscosities, and hardened iron bushings and hardened steel shafts minimize wear. There’s no packing to adjust, which eliminates common overtightening problems.

LESS PUMP & PART VARIATION The 1224A-CHC2 models for non-chocolate liquids are identical to CHC1, except the casing does not have flush and suckback grooves, for higher efficiency on thin liquids like cocoa butter. This reduces pump and spare part variation, and enables easy conversion from CHC1 to CHC2 and vice versa. Seal kits enable low-cost conversion of existing Viking Universal Seal pumps to the O-Pro™ Barrier Seal.

FOOD SAFETY - EC1935 COMPLIANT The pumps are constructed of food grade materials and carry the EC1935 mark to limit leaching of harmful substances into food, and are suitable for use on low hazard foods like chocolate, according to your HACCP plan.

SIMPLE MAINTENANCE O-rings are replaceable with the pump in-place, when configured with spacer couplings allow space to remove the O-Pro™ Barrier Seal. Jack screws in seal kits allow easy O-Pro™ Barrier Seal removal. Proven O-ring sealing technology means low cost seal replacement. Recommended re-greasing interval is every 500 hours of operation.

O-PRO™ BARRIER SEAL BUSHING The O-Pro™ Barrier Seal combines a bracket bushing and seal gland, with double O-ring seals, to seal chocolate out of the bracket and food grade grease in to provide lubrication for the bracket bushing

DRILLED IDLER The idler gear features a hardened iron bushing, extra clearances, and holes drilled through to ensure flow between the idler and pin, preventing chocolate from burning

NAMEPLATE - EC1935 COMPLIANT Pump nameplate features the EC1935 compliant cup and fork symbol to provide assurance of food-compatible materials of construction

- Specifications

Materials of Construction

- Casing, Head, Bracket & Idler: Cast Iron (except H/HL idlers powdered metal, Q idler hardened steel)

- Rotor: Steel (Sizes H, HL, K, LQ, LL, Q); Ductile Iron (Sizes KK, LS, QS)

- Shaft: Hardened Steel

- Bracket & Idler Bushings: Hardened cast iron

- Seals: Food grade gaskets and FDA FKM O-rings

- Lubricants: Food grade grease

- Jacketing: Jacketed heads and brackets standard to enable melting chocolate before startup

Performance

- Maximum Chocolate Temperature: 225°F / 107°C

- Maximum Chocolate Differential Pressure: 200 PSI / 14 BAR

CHC1 Model for Cocoa Liquor, All Chocolates, Pastes (≈5,000 to 200,000 cPs) Max Speed RPM Ports CHC2 Model for Cocoa Butter, Oils, Lecithin (≈1 to 5,000 cPs) Max Speed RPM Size Type Location H1224A-CHC1 280 1.5" NPT 90o H1224A-CHC2 1000 H1224A-CHC1 280 2" Flange 90o H1224A-CHC2 1000 HL1224A-CHC1 280 1.5" NPT 90o HL1224A-CHC2 1000 HL1224A-CHC1 280 2" Flange 90o HL1224A-CHC2 1000 K1224A-CHC1 190 2" NPT 90o K1224A-CHC2 780 K1224A-CHC1 190 2"/3" Flange 90o K1224A-CHC2 780 KK1224A-CHC1 190 2" NPT 90o KK1224A-CHC2 780 KK1224A-CHC1 190 2"/3" Flange 90o KK1224A-CHC2 780 LQ1224A-CHC1 125 3"/4" Flange 90o LQ1224-CHC2 640 LL1224A-CHC1 125 3"/4" Flange 90o LL1224A-CHC2 520 LS1224A-CHC1 125 3"/4" Flange 90o LS1224A-CHC2 640 Q1224A-CHC1 100 4" Flange 90o Q1224A-CHC2 470 QS1224A-CHC1 100 *4"/**6" Flange *90o/**180o QS1224A-CHC2 470 - Resources

- Brochures

- Videos

Rent product

Interested in renting Viking Pump - Chocolate Pump? Please fill in the form below and we will get back to you in the shortest time.

{formbuilder:86391}