Your Cart is Empty

Rogers - KNW Series Oil-Free Air Compressors

ROGERS KNW Series machines are designed, manufactured, assembled and tested to be the longest lasting and most energy efficient oil-free compressors in the world.

Superior Design, Superior Standards

The Rogers KNW Series assembly is designed and constructed to exacting quality standards. These standards result in assemblies with long operating life, minimum maintenance, and low operating costs.

Oil-Free, Risk Free

Rogers KNW Series rotary screw compressors deliver 100% oil-free air for your critical applications.

Oil-free air allows you to produce the highest quality products, lower your costs, protect your employees and the environment across industries. Rogers KNW Series air compressors are the perfect oil-free solution.

"Class Zero Oil-Free Air"

All models meet ISO 8573-1 Class 0 for oil aerosol, liquid, vapor and silicon.

Rogers Machinery Is Your Air Compressor Solution

- If you want the freedom to customize a compressed air solution that works for your specific requirements.

- If you are looking for an air compressor that is reliable and has a proven history of performing in the most difficult of applications.

- If local manufacturing and 24/7 service support are important to you.

- If you are looking for ways to save energy and reduce overhead in your facility.

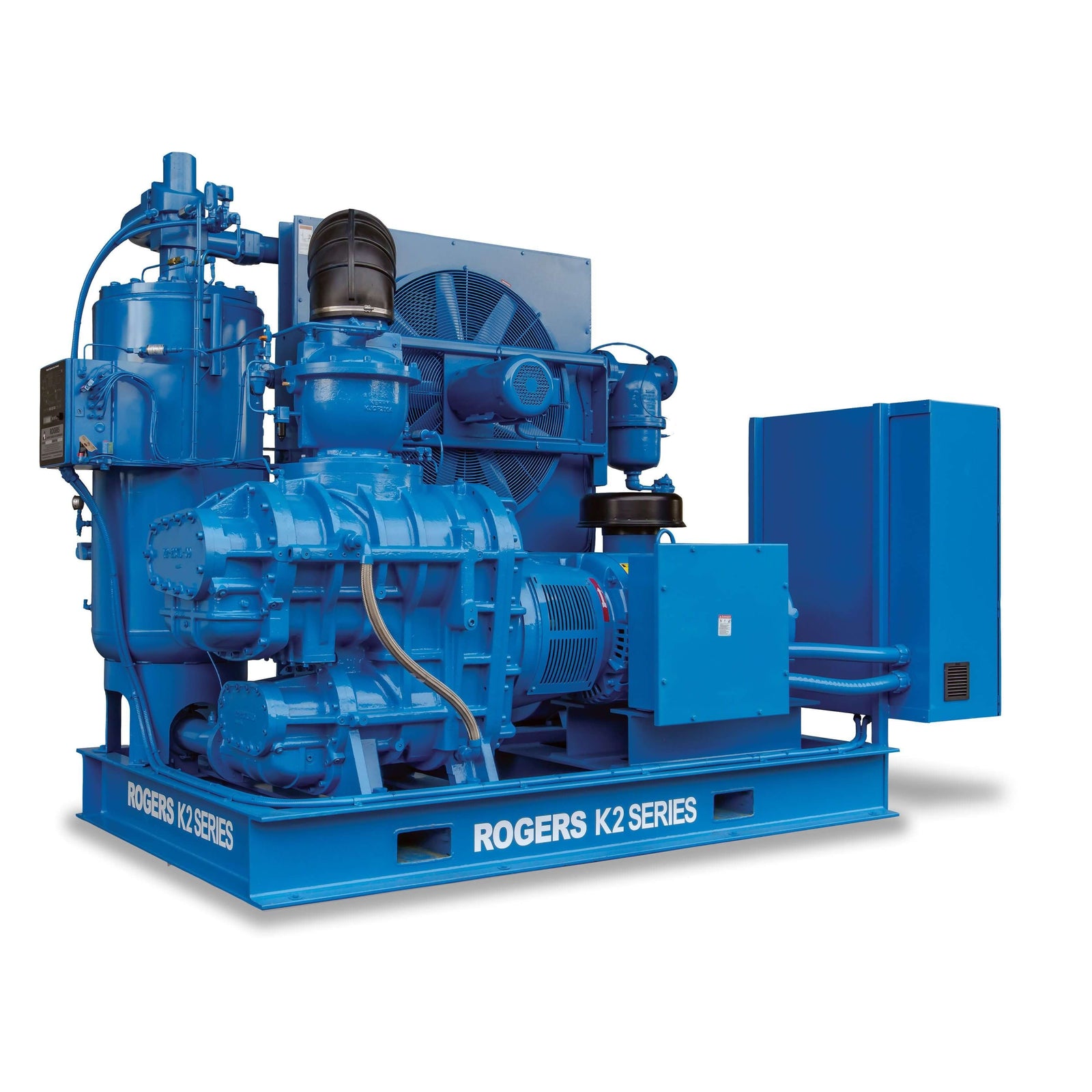

KNW History

The Rogers KNW Series oil-free air compressor was developed in the early 1980's, when customers were demanding a new level of compressed air cleanliness.

It was about this time that Kobelco started a partnership with Rogers Machinery, who eventually fully developed the product that people throughout the world know as the Rogers KNW Series.

Now this product line is engineered, assembled, and tested at the Rogers Machinery corporate facility in Portland, Oregon. Kobelco Compressors Manufacturing Indiana (KCMI) supplies the air-end.

-

This product price is available on request only

Product details

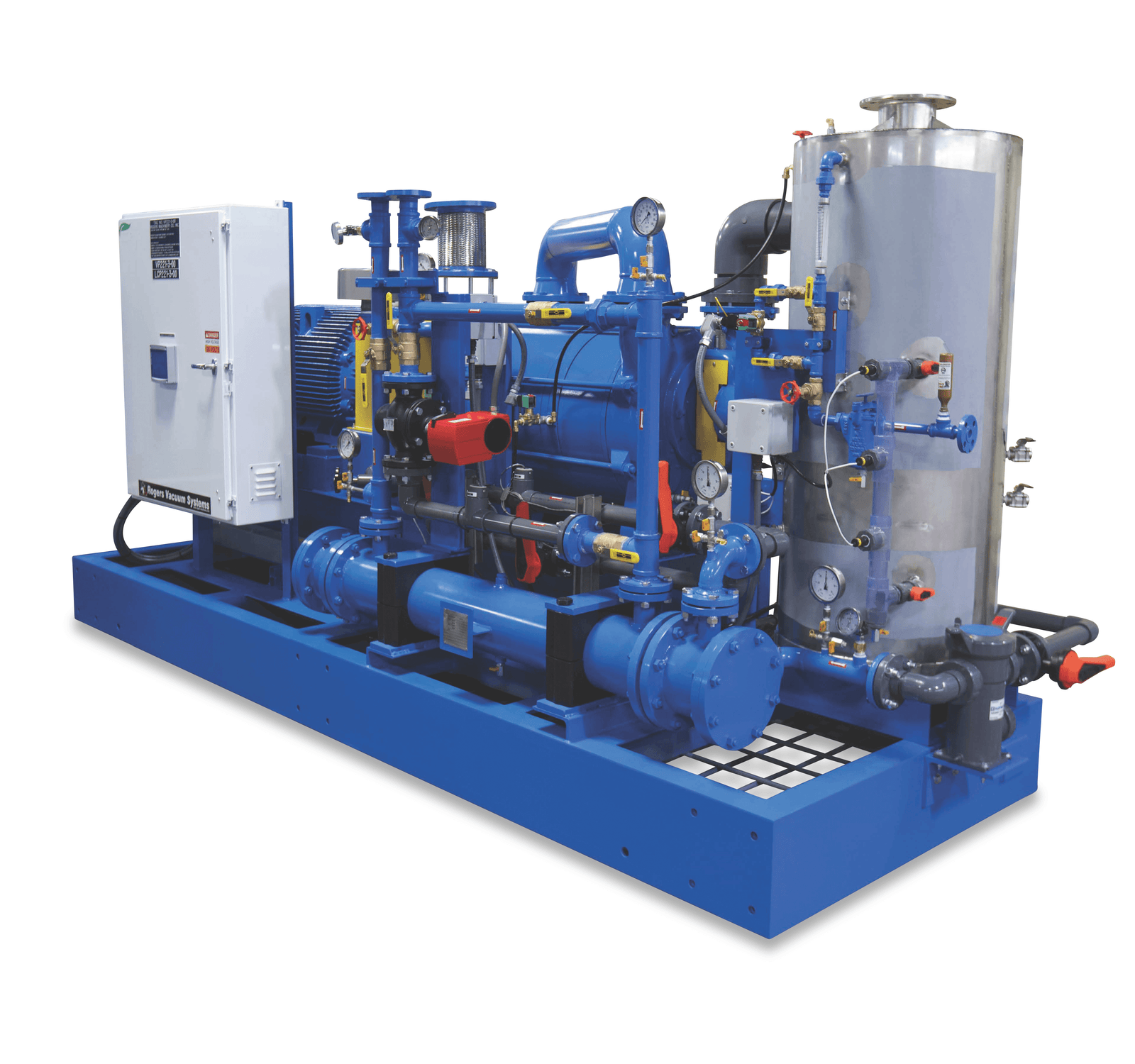

The Rogers KNW Series is our oil-free rotary screw air compressor that is designed, engineered and assembled Portland, Oregon.

-

Proven Technology ROGERS KNW Series Rotary screw design is the preferred choice for reliability. energy efficiency and serviceabiity. The Rogers KNW Series oil-free compressors are designed with a 150,000 hour bearing life providing unparraled performance for your application. Two Stage Design Heavy duty, two-stage compression module with thrust balancing for long bearing life in each stage. Designed, tested and manufactured in he USA. No other oil-free compressor manufacturer has made that commitment to the North American market. Coated Rotors ASTM 1144 steel rotors with exclusive PTFE coating on rotors and shafts for maximum efficiency and corrosion protection. Gears and bearings are lubricated by a unique motor driven oil pump that provides positive lubrication prior to start-up, through operation and after shutdown. This is an especially important features for VFD module and not available on competitive offerings. Unique Design Features Key design features ensure long air end life. All features may not be available on competitive models.

- Non-contact maintenance free air and oil seals

- Thrust balance compensation

- Cooling jackets

- Duel vents-to-atmosphere ensure oil-free air

- Vacuum degassed thrust and radial bearings

- Premium AGMA rated gears

- All models meet the requirements of NFPA 99 for use a medical air compressor

-

Flow (SCFM) 72 - 2,400 Power (HP) 20 - 500 Pressure (PSIG) 40 - 150

-

View Rogers KNW Series case studies and blog posts.

- Description

Proven Technology ROGERS KNW Series Rotary screw design is the preferred choice for reliability. energy efficiency and serviceabiity. The Rogers KNW Series oil-free compressors are designed with a 150,000 hour bearing life providing unparraled performance for your application. Two Stage Design Heavy duty, two-stage compression module with thrust balancing for long bearing life in each stage. Designed, tested and manufactured in he USA. No other oil-free compressor manufacturer has made that commitment to the North American market. Coated Rotors ASTM 1144 steel rotors with exclusive PTFE coating on rotors and shafts for maximum efficiency and corrosion protection. Gears and bearings are lubricated by a unique motor driven oil pump that provides positive lubrication prior to start-up, through operation and after shutdown. This is an especially important features for VFD module and not available on competitive offerings. Unique Design Features Key design features ensure long air end life. All features may not be available on competitive models.

- Non-contact maintenance free air and oil seals

- Thrust balance compensation

- Cooling jackets

- Duel vents-to-atmosphere ensure oil-free air

- Vacuum degassed thrust and radial bearings

- Premium AGMA rated gears

- All models meet the requirements of NFPA 99 for use a medical air compressor

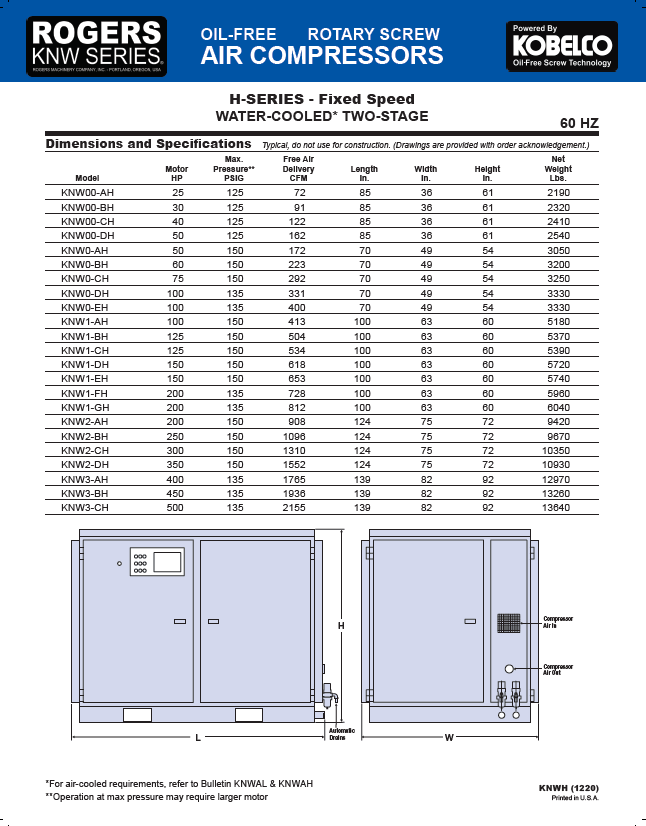

- Specifications

Flow (SCFM) 72 - 2,400 Power (HP) 20 - 500 Pressure (PSIG) 40 - 150

- Performance Specs

- Brochures

- Articles

View Rogers KNW Series case studies and blog posts.

Rent product

Interested in renting Rogers - KNW Series Oil-Free Air Compressors? Please fill in the form below and we will get back to you in the shortest time.

{formbuilder:10226}