Your Cart is Empty

Petrochem

Compressed Air, Vacuum Systems & Blowers for Petrochem

Rogers Machinery offers safe and effective solutions for the petrochem industry. Rogers assists oil & gas industry customers with developing clean, safe processes that satisfy the standards of the industry with energy saving compressed air, vacuum systems, and blowers.

Successful Petrochem Projects

Oil-free Air Compressors

427+

Lubricated Air Compressors

12+

Considerations for Petrochem Compressed Air, Vacuum Systems & Blowers

Safety and compliance with environmental regulations drive changes in the petrochem industry. Even a by-product like compressed air condensate must often be managed as a hazardous waste. In processes like refining, hazardous site conditions require that compressed air and vacuum systems must be customized to ensure employee and facility safety. Compressed air and vacuum systems audits can identify opportunities for improvement.

The challenge of tight margins in the petrochemical industry drives the quest for more energy efficient best practices to reduce cost. One of the best ways to save energy is to evaluate compressed air and vacuum systems, which are used throughout the oil & gas industry. Whether a petrochem application requires a single standard vacuum pump or a complex vacuum system, optimizing the technology addresses the bottom line.

The demands of petrochemical applications also require the highest reliability in compressed air, vacuum systems, and blowers. Processes like refining operate 24/7. Any unintended shutdown can be complicated, resulting in huge financial impacts. Reliable equipment like vacuum pumps can ensure that refining processes like distillation, drying, extraction, evaporation, reaction operate with a minimum of downtime.

Petrochem processes must also comply with stringent industry and environmental regulations. In many cases, air compressors operating in petrochemical plants are required to meet API 672 and Class 1, Division 2. The right compressed air, vacuum, and blower equipment can ensure that regulations are met within budget.

Highlighted Content

Increase the Energy Efficiency of your Compressed Air System

Compressed air is useful for many reasons; however, it is expensive to produce. The total cost of ownership should be a factor when dealing with a compressed air system.

ReadWhy Oil-Free Air?

There is an old adage which is also a law of physics; what goes in will eventually come out. This applies to compressor lubricant in oil-flooded rotary screw compressors.

ReadRogers KNW Series compressors provide versatile oil free air for the petrochem industry. The Rogers K Series of lubricated rotary screw compressors and vacuum pumps offer reliability and performance for these applications as well. In addition, Rogers Machinery provides solutions for the petrochem industry from a number of leading brands that specialize in compressed air, vacuum, and pumping for petrochem applications.

- MD-Kinney vacuum pumps, side channel blowers and compressors bring energy efficient vacuum supply to processes like crude oil distillation.

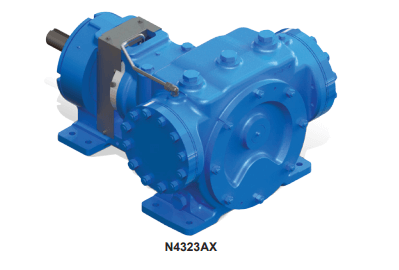

- Viking pumps are specialized for processing petrochem products and byproducts like biofuels, caustic, crude oils, diesel, red dye, gasoline, hot wax, and black liquor soap.

- Zeks air treatment products include air dryers and cooling source dryers for clean, dry compressed air with and without refrigeration for the petrochem industry.

- SPXFlow technology provides products – Dyers, Filters and Mist Eliminators – to help preserve compressed air equipment used in petrochem processes.

- FS Elliott centrifugal compressors deliver safe, reliable compressed air that can meet API 672 if needed.

- Parker nitrogen generation products can be used for inerting emissions in oil refining and for sealing and blanketing natural gas.

Explore Rogers Machinery’s compressed air, vacuum systems, and blowers for the petrochem industry.

German Made

Dry Screw Vacuum Pump

from $34,864.00

Viking Pump

Viking Pump - API Compliant Pumps

Request a Quote

ZEKS

ZEKS - ZPB Series Compressed Air Dryer

Request a Quote

Rogers Machinery

Rogers - KNW Series Oil-Free Rotary Screw Air Compressor

Request a Quote

Pneumatic Products

Pneumatic Products - CHA Series Compressed Air Dryer

Request a Quote

FS Elliott

FS-Elliott - Polaris 300 Industrial Air Compressor

Request a Quote

FS Elliott

FS-Elliott - Polaris 500 Industrial Air Compressor

Request a Quote

FS Elliott

FS-Elliott - Polaris 400 Industrial Air Compressor

Request a Quote

FS Elliott

FS-Elliott - Polaris 600 Industrial Air Compressor

Request a Quote

Hycomp

Hycomp - Helium Compressor

Request a Quote

MD-Pneumatic

MD-Pneumatics - PD Plus 4000 Series Rotary Positive Displacement Blowers

Request a Quote

MD-Pneumatic

MD-Pneumatics PD Plus 3200 Series Rotary Positive Displacement Blowers

Request a Quote

MD-Pneumatic

MD-Pneumatics - PD Plus Blowers 5500 Series Rotary Positive Displacement Blowers

Request a Quote

MD-Pneumatic

MD-Pneumatics - Qx Series Rotary Positive Displacement Blowers

Request a Quote

MD-Pneumatic

MD-Pneumatics - PD Plus 900 Series Rotary Positive Displacement Blowers

Request a Quote

MD-Pneumatic

MD-Pneumatics - PD Plus 1200 Series Rotary Positive Displacement Blowers

Request a Quote

MD-Pneumatic

MD-Pneumatics - CP Series Rotary Positive Displacement Blowers

Request a Quote

Rogers Machinery

MD-Pneumatics - Qube Blower Packages

Request a Quote