Your Cart is Empty

Rogers KNW Series

Rogers Machinery News is your place for informative, educational articles and case studies about air compressors, pumps, blowers & vacuum systems. Our goal is to provide useful information that will help you make informed product decisions – all to keep your facilities running efficiently with maximum uptime.

16 news articles

Why Oil-Free Compressed Air?

Compressed air users are becoming increasingly intolerant of contamination in their systems, whether it's in a patient’s lungs, food and beverage products, pharmaceuticals, or semiconductors. Eliminating the risk of contaminated end product, saving money in energy use, and maintenance are only a few of the benefits.

What is a Compressed Air System?

Compressed air systems require many components to run smoothly. In order to get the most out of your compressor and avoid costly air quality issues, you’ll need more than just a compressor in your system to run your facility. In this article, we will break down each component so you know exactly what your system needs. To learn more about compressed air in general, start with these articles.

Estimate read time: 6 minutes

8 Ways to Increase the Energy Efficiency of your Compressed Air System

Compressed air is essential for many industrial applications. However, it is expensive to produce. The total cost of ownership should be a factor when considering a compressed air system. Here are eight ways to increase the efficiency of your compressed air system.

Estimated read time: 7 minutes

Engineering Laboratory Switches To A Reliable Compressed Air Supplier

After becoming frustrated with unreliable air compressors, poor support, and low-quality compressed air, Schweitzer Engineering Laboratories decided to rely on Rogers for all their compressed air needs.

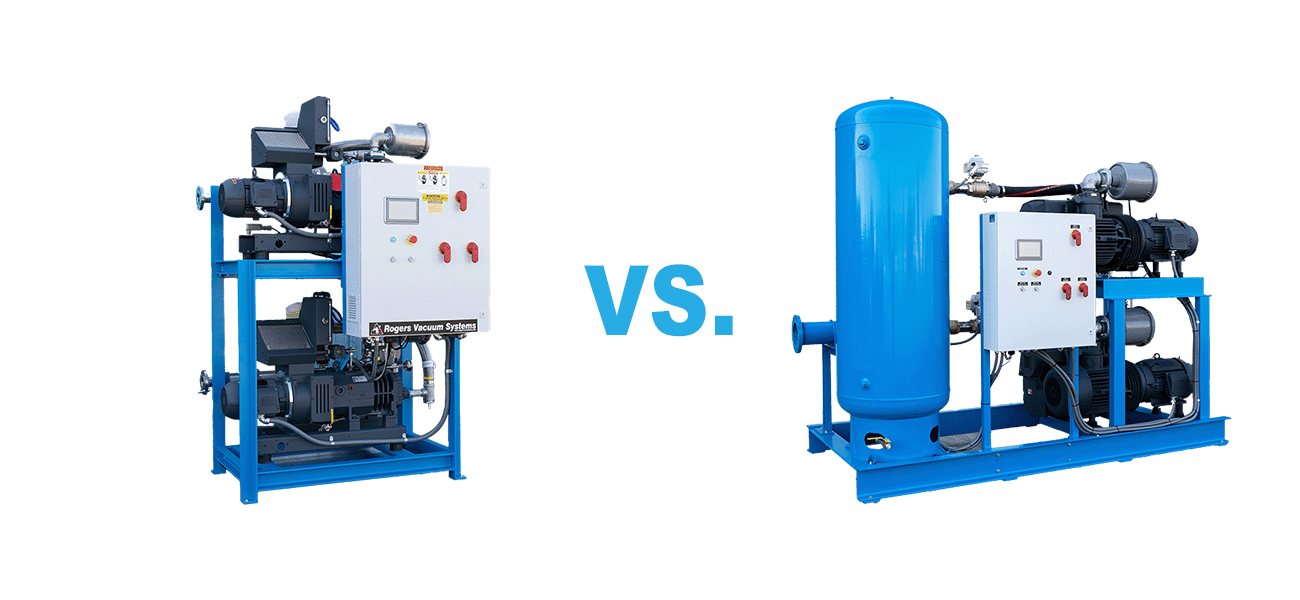

Vacuum Receivers: Full of Vacuum or Full of Myth?

In this article, we’ll discuss some of the uses for receiver tanks for positive pressure systems where the pressure inside the system is greater than atmospheric pressure, and the uses, or lack thereof of, receiver tanks in vacuum systems where the system pressure is less than atmospheric pressure.

Rogers Helps Energy Company Achieve Energy Efficiencies During Expansion Project

Talen had plans to expand their coal power plant in Montana and needed to have an energy efficient and reliable compressed air system for manufacturing process. Rogers was there to help and provided support, even after the sale.

Preparing Your Compressed Air System for Winter

Winter is coming… and colder temperatures that come with it. In this article, we'll discuss methods to prepare your compressed air system for the winter months, and how to keep shutdowns at a minimum.

Downtime Wasn't an Option for LabCorp

As one of the largest clinical laboratory networks in the world, LabCorp, is reliant on efficient energy for patient care testing to serve hospitals and doctors in their area. That is why they needed a knowledgeable, reliable, and trustworthy service company for their air compressor system.

Fujimi Goes Oil-Free And Saves With An Energy Incentive Payback Program

Fujimi was able to get energy savings of over 500,000 kWh annually by working with Rogers to implement an oil-free compressed air system that included three Kobelco KNW Series air compressors!

Preparing Your Compressed Air System For Summer

The summer heat may be fun for those of us that can take a vacation, but likely your compressed air system doesn’t get a break. Learn how to get your compressor ready for the hot months!