Your Cart is Empty

High Tech/Electronics/Aerospace

Rogers Machinery News is your place for informative, educational articles and case studies about air compressors, pumps, blowers & vacuum systems. Our goal is to provide useful information that will help you make informed product decisions – all to keep your facilities running efficiently with maximum uptime.

9 news articles

Process Vacuum Applications & Oil-Free Technology

In this article, we dive into the differences between utility and process vacuum, measurement guidelines, and specifying vacuum systems to process applications for maximum system efficiency.

Written by: Bryan A. Jensen

How to Select the Right Dryer for Your Air Compressor

This Compressed Air Dryer Buying Guide will help you select the right air dryer for your air compressor and specific application requirements.

The Second Stage of Energy Savings

Find out the details about how a Rogers Machinery was able to provide energy efficient VFD Air Compressor System Solution lead to savings of over 212,000 KWh and $15,000 in energy costs for the Safeway Milk Plant.

Supporting Customers Internationally With Engineered System Solutions

When a high-tech electronics customer came to us for a vacuum system solution at their Ireland plant, we took on the unique and challenging project taking steps to ensure the system met EU standards without sacrificing performance.

How to Select the Right Air Compressor for a New Plant

Selecting a new air compressor can be difficult, but Rogers is here to help. It is the perfect time to solidly assess the requirements to select the right air compressor type and size that is critical to your plants manufacturing process. This article will discuss how to select the best air compressor for your needs.

High-Tech Electronics Customer Gets A 'Boost' To Vacuum Performance Saving Over $200K In Energy & Water Costs

Before we get into the nitty gritty, here are the broad strokes of a project we completed recently in New Mexico. As you’ll see, it started out with a common problem which all facility engineers and operators face...

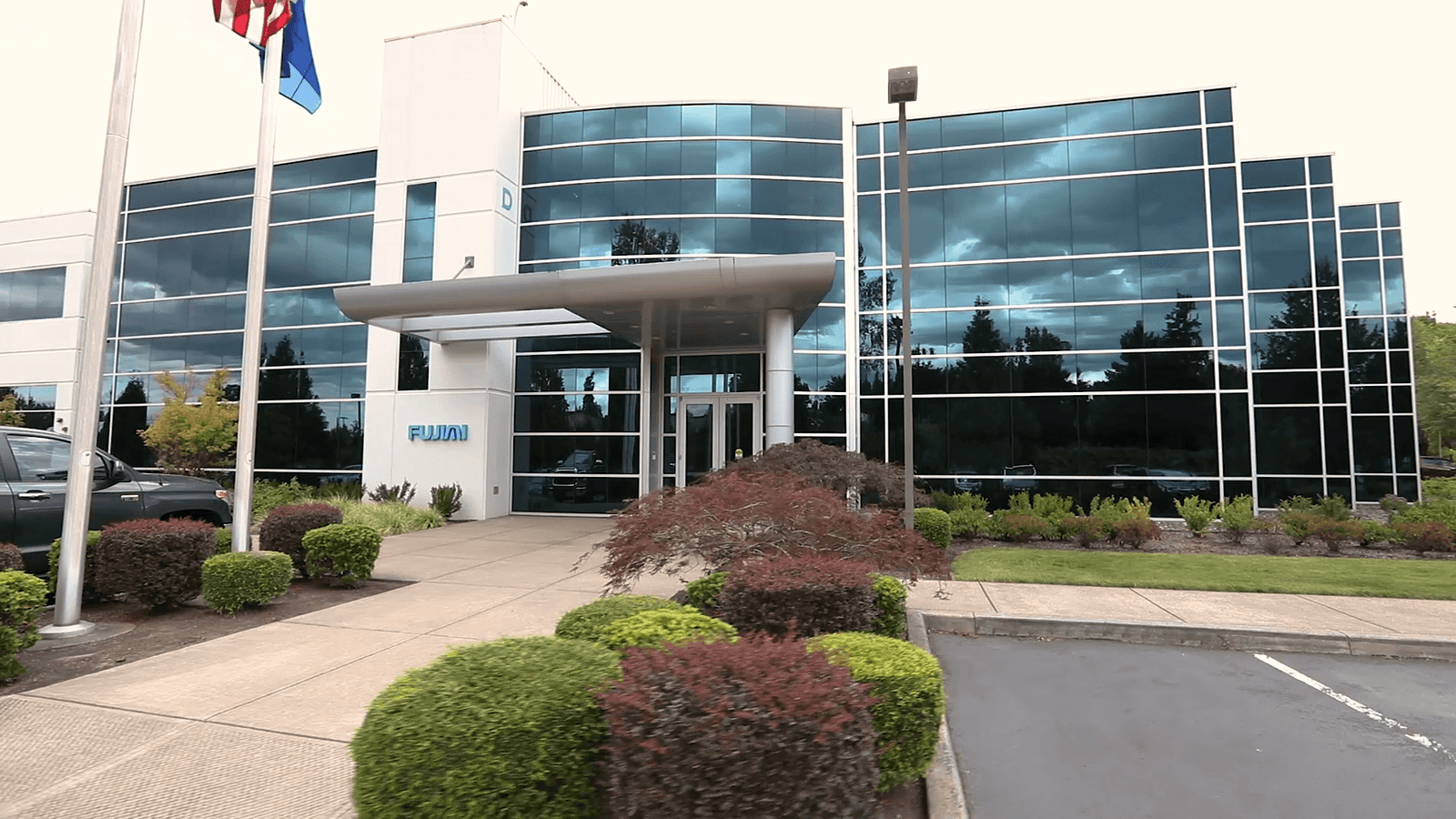

Fujimi Goes Oil-Free And Saves With An Energy Incentive Payback Program

Fujimi was able to get energy savings of over 500,000 kWh annually by working with Rogers to implement an oil-free compressed air system that included three Kobelco KNW Series air compressors!

International Wire Compressor System Upgrade Transfers Energy Savings to its Bottom Line

International Wire was able to get energy savings of over 400,000 kWh annually by working with Rogers to implement an oil-free compressed air system that included Kobelco KNW Series air compressors with a heat recovery system!

Success Story: Fujimi Wilsonville

Fujimi Wilsonville was able to get energy savings of over 180,995 kWh annually, electrical cost savings of $11,889 annually and a simple payback of 8 months through the implementation of a reliable, clean compressed air system.