Your Cart is Empty

Need help? Call us: 1 503 639 0808

Unmatched Service & Support

Rogers Machinery cares. We go above and beyond – every time – to keep your facility running smoothly and on schedule.

Let us treat you like family. High Performance Products that Stand the Test of Time

Our robust, American-made air compressors and vacuum pumps lead the industry in longevity and durability. You’ll be impressed with our large selection of efficient and reliable compressed air system products. We guarantee it!

Find out why our premium-quality systems are the most dependable on the market. The Right Solution for Your Application… No Matter What

No cookie-cutter systems here. We have a large selection of products and the flexibility to create highly customized systems. Rogers Machinery serves a wide variety of industries and facilities – including ones like yours.

Let’s talk. We’d love to discuss what we can do for your facility. Regional Accessibility with National Reach

We call the Pacific Northwest home, but we serve many domestic and international customers. Our reputation precedes us wherever we go, and we meet our customers wherever they are.

Learn more about our Pacific Northwest compressors and our locations nationwide. Atlanta Promotion - Free Shipping

We are now offering free shipping on all Assembly Orders shipped to Georgia.

Learn more here Family Owned

Rogers started as a locally grown, family-owned business, building air compressor solutions right here in the USA, and has been for over 70 years.

We are proud to be a locally grown and American made company.

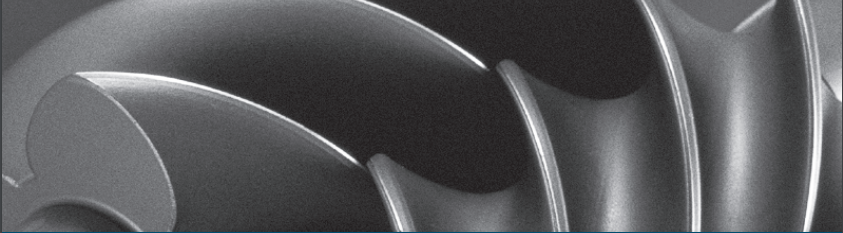

Rogers KNW Series

Design Features

Click to Enlarge

Two-Stage Design

Rogers KNW Series rotary screw compressors deliver 100% oil-free air for your critical applications. Heavy duty, two-stage compression module with thrust balancing for long bearing life in each stage. Designed, tested and manufactured in the USA. No other oil-free compressor manufacturer has made that commitment to the North American market. Also available as single stage design for low pressure applications.

Coated Rotors

ASTM 1144 steel rotors with exclusive PTFE coating on rotors and shafts for maximum efficiency and corrosion protection. Gears and bearings are lubricated by a unique motor driven oil pump that provides positive lubrication prior to start-up, through operation and after shutdown. This is an especially important feature for VFD models and not available on competitive offerings.

Unique Design Features

Key design features ensure long air end life. All features may not be available on competitive models. Features Include:

- Non contact maintenance free air and oil seals

- Thrust balance compensation

- Cooling jackets

- Dual vents to atmosphere ensure oil-free air

- Vacuum degassed thrust and radial bearings

- Premium AGMA rated gears

- All models meet the requirements of NFPA 99 for

use as a medical air compressor

Superior Components

Thrust balance pistons on each stage provide maximum air end life. The stainless steel, non wearing air and oil seals with dual vents to atmosphere, assure oil-free air. These features are not found on competitive models. Competitors use carbon rings with single vents and no thrust balance.

Click to Enlarge

Precision Machined Gears

Click to Enlarge

Vacuum Degassed Bearings

Compressor Control and Monitoring

The Rogers KNW Series oil-free rotary screw air compressor uses an Allen Bradley programmable controller to control and monitor compressor operation. Operations include:

- Controlled sequential starting and stopping

- Pressure control

- Protection from conditions that could damage the compressor.

Additional features include:

- Pilot lights, viewable from a distance, are provided for indication of operating conditions

- An audible alarm is provided for alarm annunciation

- Push buttons are provided for specific control functions, allowing continued compressor operation in the event the terminal is off-line

HMI Terminal

The HMI terminal is an LCD graphic display with touch screen. The HMI terminal shows operating conditions, pressures, and temperatures. Messages are sent to direct the operator for service, pre-alarms, and alarms, and will be shown when necessary. Required settings for pressure control, temperature alarms, and control time delays are viewable and may be modified using the touch screen. The HMI terminal will automatically “dim” to a sleep condition if inactive and awakens on any touch contact. A universal communication module is also available to handle virtually any Ethernet or Serial driver. They can be designed according to customer preference. The VFD data, if applicable, includes KW, amps, hertz and rpm.

Data Collection

The USB through door port is provided below the HMI. Also included is an SD memory card. Both provide the ability to download:

- Data loggers

- Alarm history

- Compressor status report

- Daily report from the HMI

These files can then be opened using Microsoft Excel. External memory (USB, SD) provides the ability to update or modify the existing HMI project.

Pressure & Temperature Monitoring

Compressor pressure and temperatures are monitored using smart sensor technology and I/O link communication. Real time pressure and temperature values are displayed on the HMI. Pressure and temperature trends are also on the HMI. All values are also available for remote monitoring. I/O link is specifically designed for communication with smart sensors and allows detailed diagnostics of sensor health.

Click to Enlarge

Allen Bradley CompactLogix Series PLC

Click to Enlarge

HMI Terminal Pressure Page

Click to Enlarge

Universal Module for communication

with facility management system. Typical

protocols include Modbus and BACNet

Click to Enlarge

HMI Terminal Temperature Page

Click to Enlarge

Pressure Temperature Smart Sensors

Click to Enlarge

State of the art IO-Link Communication

Pre and Post Lubrication of Gears Bearings

Unique to Rogers KNW Series: Lubrication prior to start up, during operation and shutdown is supplied by an independent motor-driven gear pump. The compressor will not operate until oil pressure is established. The design increases gear and bearing life and is not offered on competitive models. All oil-side piping is stainless steel and has SAE leak-free fittings.

Click to Enlarge

Oil Circuit

Click to Enlarge

Independent Motor-Driven Oil Pump

Click to Enlarge

Leak-Free Fittings on Oil Circuit

Click to Enlarge

Oil Filter with Differential Indicator

Heavy Duty Input Bull Gear Design

The Input bull gear is supported on each side. Competitors use an overhung design. The labyrinth type seal used on the drive end ensures leak-free operation. Competitors use a lip seal design, which is prone to wear and leakage. These features found on the Rogers KNW Series ensure a long operating life and eliminate oil leaks.

Capacity Control: Fixed Speed or VFD

Fixed speed, also known as load-unload, provides energy-efficient operation during loaded and unloaded operation. During unloaded operation, brake horsepower is reduced to approximately 18% of full load. This reduces the overall energy cost significantly. The valve is a positive-closing disc type with orifices, using spring and air pressure to activate. Unloaded horsepower is guaranteed and repeatable. The valve is designed for 1,000,000 load-unload cycles and is easily serviced.

Click to Enlarge

VFD Control

VFD Control Flexibility

VFD control provides a narrow system pressure band, reduces inrush at start-up, and allows more frequent stops and starts. VFD control becomes less energy efficient compared to fixed speed when operated at the upper end of speed range.

Power Consumption

Click to Enlarge

Load vs Unloaded Power Consumption

Click to Enlarge

Fixed Speed vs VFD Power Consumption

Highly Efficient Cooling System

Rogers KNW Series water-cooled models feature highly efficient, removable, copper tube bundles. Internal turbulators provide optimum heat transfer with minimal pressure drop. Shells are made of carbon or optional stainless steel with an ASME stamp.

Water-cooled models include a thermostatic valve on the intercooler and an automatic shut-off valve on the cooling water inlet. Air is inside of the tubes and water is in the shell.

Air-cooled heat exchangers are made of heavy-duty aluminum with a special coating and are designed for all published operating conditions. Rogers KNW Series air-cooled models include a thermostatic mixing valve to insure proper oil temperature in changing ambient temperatures. All water and air-cooled models have oversized moisture separators with automatic drains for maximum efficiency.

Click to Enlarge

Copper tubes with internal turbulators

Click to Enlarge

Removable Tube Bundle

Click to Enlarge

Standard air cooled heat exchangers

Click to Enlarge

Thermostatic Mixing Valve

Heavy Duty Inlet Air Filter with Pre-Filter

The inlet air filter is easily accessible and includes a cleanable prefilter which extends element life. The air filter is rated at 5 microns and is 99% efficient. A filter change notice is indicated on the HMI.

Air, Oil and Water Flow Circuits

Heavy Duty, Corrosion-Resistant Finish

All Rogers KNW Series compressors are protected by a unique powder coating system. The powder coating is applied to the base, frame and enclosure. This finish is chip and corrosion resistant and keeps the compressor looking new throughout its lifetime. Other finishes are available for extreme environments.