Your Cart is Empty

Zeks

ZEKS Air Dryers, Parts, & Repair | AZ, CA, GA, ID, MT, NV, OR, TX, UT, WA

As the exclusive stocking ZEKS distributor in the Northwest, Rogers Machinery offers expertise with ZEKS air dryers, as well as ZEKS air dryer parts & service. Since 1997, Rogers Machinery engineers have provided ZEKS compressed air dryers in California, Georgia, Idaho, Montana, Oregon, Texas, Utah, and Washington.

ZEKS Compressed Air Solutions was founded in 1959, and has grown to become a leader in compressed air treatment products that optimize efficiency and reliably remove water and contaminants from compressed air. One of ZEKS’ earliest innovations was the cycling refrigerated dryer, which cycles on and off depending on actual air usage to conserve energy. ZEKS manufactures refrigerated and desiccant air dryers, filters, mist eliminators, flow controllers, and air system accessories.

ZEKS Air Dryers Line Overview

Rogers Machinery provides expert knowledge, selection assistance, installation, and service for the ZEKS line of compressed air dryers. ZEKS compressed air dryers include Refrigerated Dryers, Desiccant Dryers, Filtration and Condensate Management Equipment, and Flow Controllers. As the exclusive ZEKS distributor in the Northwest, Rogers Machinery has the knowledge to help specify the right solution for your needs, with many models in stock. Contact Rogers Machinery for assistance.

Refrigerated Dryers

Refrigerated ZEKS air dryers include the well-known HeatSink™ cycling dryers, non-cycling dryers, and models for special applications.

ZEKS is best known for HeatSink™ cycling refrigerated compressed air dryers, which are designed to cycle when flow profiles vary due to seasonal variations, shift usage, or other reasons. These dryers consume only the electrical energy necessary to meet the actual demand for dry compressed air. They offer:

- Energy saving operation during periods of low demand

- Multi-layer heat exchanger

- Precooler/reheater

- 38°F dew point air quality

- Digital dryer control

- Low pressure drop

ZEKS non-cycling refrigerated dryers can be an efficient and economical alternative where compressed air usage is consistent.

ZEKS also offers compressed air dryers engineered for high temperature and high-pressure applications.

Desiccant Dryers

ZEKS desiccant compressed air dryers achieve extremely low moisture levels for applications where environmental conditions demand it or where even minimal moisture can't be tolerated. Choose from heatless, heated purge or heated blower purge desiccant regeneration to meet application requirements.

Heatless regenerative desiccant dryers are:

- Available from 3-5,000 scfm

- Designed to achieve dew points to -40 °F or -100 °F

- Available in low noise, compact, and wall-mounted designs

- for systems with 1-1,000 hp compressors

Heated regenerative desiccant dryers use heated purge air for desiccant media regeneration and are:

- Designed to achieve dew points to -40 °F or -100 °F

- Heated blower regeneration dryers

- Available from 150-8000 scfm

Purge regenerative desiccant dryers provide their own source of regeneration air, so the full air compressor output is available downstream They are:

- Designed to achieve dew points to -40 °F

- Heated blower regeneration dryers

- Available from 150-8000 scfm

Filtration

ZEKS Mist Eliminators are large, high-efficiency coalescing filters that combine:

- extremely low pressure drop

- large, depth-bed filter element to extend service life

- an ASME-rated vessel

- 125-8,000 scfm

- air systems with 30-2,000 hp compressors

Condensate Management

ZEKS condensate management solutions keep compressed air equipment running optimally. Oil/water separators separate compressor lubricant carryover from liquid condensate for disposal. Condensate drains ensure air compressor, air dryer, filter and receiver performance. Condensate drains are available as:

- No air-loss drains for discharging clean or heavily emulsified condensates

- Motorized ball valve drains for highly viscous condensate and pressures up to 720 psi

- Pneumatic no air loss condensate drains that require no electricity </ li>

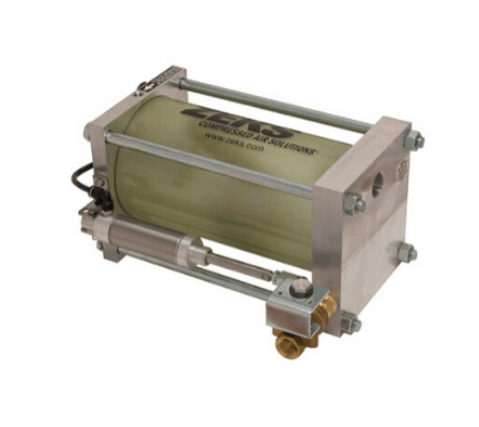

Flow Controllers

Flow Controllers help to reduce energy waste and improve air compressor efficiency by precisely controlling pressure and flow. They can operate to control forward pressure and flow, or to control backward flow to protect critical processes, or a combination of the two. Flow controllers are available for:

- 2"-8" flanger connection sizes

- air systems with operating range from 835-19,200 scfm

ZEKS Air Dryer Products

ZEKS

ZEKS - ZBB Series Compressed Air Dryer

Request a Quote

ZEKS

ZEKS - CDAN, CDAW Series Compressed Air Dryer

Request a Quote

ZEKS

ZEKS - HDF Series Mist Eliminator Filter

Request a Quote

ZEKS

ZEKS - HSG Series Compressed Air Dryer

Request a Quote

ZEKS

ZEKS - HSG/HSF Series Compressed Air Dryer

Request a Quote

ZEKS

ZEKS - HSGM Series Compressed Air Dryer

Request a Quote

ZEKS

ZEKS - HTB Series Compressed Air Dryer

Request a Quote

ZEKS

ZEKS - HSK Series Compressed Air Dryer

Request a Quote

ZEKS

ZEKS - MPS Series Compressed Air Dryer

Request a Quote

ZEKS

ZEKS - NC Series Compressed Air Dryer

Request a Quote

ZEKS

ZEKS - NCE Series Compressed Air Dryer

Request a Quote

ZEKS

ZEKS - SCFX Series Compressed Air Dryer

Request a Quote

ZEKS

ZEKS - PNA Series Compressed Air Dryer

Request a Quote

ZEKS

ZEKS - ZHA Series Compressed Air Dryer

Request a Quote

ZEKS

ZEKS - ZPB Series Compressed Air Dryer

Request a Quote

ZEKS

Pneumatic - No Air-Loss Drain

Request a Quote

ZEKS

ZEKS - Hydronix Compressed Air Dryer

Request a Quote

ZEKS

ZEKS - HPHSG Series Compressed Air Dryer

Request a Quote

ZEKS Air Dryer Parts

When you need ZEKS air dryer parts, Rogers Machinery has multiple locations throughout the Northwest to serve you. We stock an inventory of genuine ZEKS air dryer parts, accessories, and ZEKS air dryer manuals for regular maintenance and repair.

ZEKS Air Dryer Repair Service

Our in-house staff of service technicians is factory trained and authorized to perform ZEKS air dryer repair service. We use genuine ZEKS air dryer parts and have the expertise to keep your ZEKS compressed air dryers operating at their highest efficiency. Contact Rogers Machinery for any ZEKS air dryer repair needs.

ZEKS Air Dryer Applications (or Industries)

Compressed Air Dryers Video

Types of Compressed Air Dryers

ZEKS Air Dryer Resources

Learn more about how Rogers Machinery customers use ZEKS compressed air dryers for real life solutions in a variety of industries.

Winner of Global Best Projects Award Utilizes Rogers Engineered Compressed Air System

Rogers Helps Energy Company Achieve Energy Efficiencies During Expansion Project