Your Cart is Empty

Supporting Customers Internationally With Engineered System Solutions

When a high-tech electronics customer came to us for a vacuum system solution at their Ireland plant, we took on the unique and challenging project taking steps to ensure the system met EU standards without sacrificing performance.

Our History

In our 75+ years of business, we have sold equipment all over the globe. Much of the equipment that is sold, designed, and built by Rogers Machinery Company, Inc. ends up in the United States, Canada, Central and South America. A US based company, we are a nimble organization that has always taken on design challenges to make our equipment meet the needs of our customer base wherever they are located.

Our rich history and indelible reputation in the Pacific Northwest continues to fuel our growth in new and exciting projects abroad. Supporting our customers as they expand into international markets is a key piece to our growth.

Figure 1: Rogers Machinery supplies critical vacuum equipment to the electronics industry in the US and abroad. Above are vacuum systems destined for Europe.

A Customer Case Study

One of our valued customers started in Oregon in the 1970’s and has since expanded out across the US and abroad into Asia and Europe. When they asked us to provide them with the same reliable vacuum pump equipment that we provide to each of their locations here in the US, we were happy to assist.

Any manufacturing equipment, including vacuum pumps, going to the European Union needs to carry with it the CE mark. To place the CE mark on any piece of equipment, one must comply with the directives and standards associated with the CE mark. Similarly, one would need to comply with the directives and standards set forth by the UL or CSA governing bodies to carry either, or both, of those marks on their equipment.

Figure 2: All equipment is tested by our Rogers Machinery engineering staff prior to shipment to customers to verify operation and performance.

What are some key differences between the US and Europe when it comes to electrically powered vacuum pumps?

1 – FREQUENCY / HERTZ

There is the impact of the local utilities to consider. Hertz is a unit of measurement for frequency. 1 Hertz means there has been one cycle per second. In the US, and many of our neighboring countries to the north and south, we have 60 Hz electrical power provided to us by our local utilities. In Europe the power is 50 Hz. In a very simplified summary – this means that the power in the US cycles at 60 times per second (60 Hz) and in Europe their power cycles 50 times per second (50 Hz). Some electrical equipment is cross listed for 50/60 Hz operation meaning it could operate in both environments without any effect on its performance.

Figure 3: Low voltage control panel made by Rogers Machinery compatible with 60Hz/120VAC and 50Hz/230VAC power.

However, other components, such as electric motors are often not cross listed for frequency operation. This means that you cannot take a 60 Hz rated motor and expect it to perform as it would in a 50 Hz operation.

2 – VOLTAGE

Local utility voltages are the next major differences between the US and Europe. In the US, when you plug your phone or toaster into a standard wall outlet you are plugging into a 120-volt powered circuit in your home or office. This power is often displayed as 1ph/60Hz/120-volt. Meaning there is one phase of power (one powered wire and one neutral wire), the power is cycling at 60 times per second, and the voltage of the electricity is 120 volts.

If you plug into a wall outlet in your home in Europe, chances are you will be plugging into a 1ph/50hz/230-volt powered circuit. Notice not only did the frequency of the power change, but also the voltage changed.

Control power circuits are often 120-volt in the US or 230-volt in Europe. As stated earlier, many components are cross listed so that isn’t much of a concern for the design where you could plug your equipment into the wall in the US or in Europe and it would act and perform the same regardless of location.

Where we see bigger impacts are for the main power which we are using to drive our electric motors. In the states, for this customer, we have provided 460-volt motors which require 3 phase/60 Hz/460-volt power from the local utilities.

In Europe, there is no 460-volt power, and instead their equivalent is 400-volt power that is 3 phase/50 Hz/400-volt. Not often is higher voltage equipment like this cross listed for use with multiple frequencies (50 Hz vs. 60 Hz) but also for multiple voltages without significant wiring changes. By selecting the right motor for the application and utilities available many problems are easily mitigated.

Our Engineered System Solutions Are Built To Your Specifications

Learn more about how we work with you and if an engineered vacuum, compression or pump system is best for your specific needs.

CE + CE + CE ≠ CE compliance

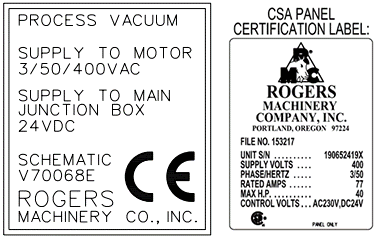

Figures 4 & 5: Examples of CSA and CE labels as they would appear on the respective pieces of equipment, predominantly on the electrical control panels.

Items that carry any or all these marks can vary greatly in size and complexity from a simple wiring terminal made of some molded plastic and a few metal bits to your computer – an intricate network of fine mechanical components working in sync with complex electrical components, circuitry, microprocessors, etc.

Making a fully functioning vacuum pump assembly complete with its own control panel requires electrical and mechanical components be CE marked to know that the components we are choosing are individually compliant with the CE directives and standards. However, it is not simply enough to take a CE marked component and integrate it with another CE marked component made by the same or different company for the same or a different purpose.

The CE directives and standards are implanted to make sure that regardless of the origin of the design and implementation of any CE marked equipment will be safe for use in the European market. Safety does not only pertain to the safety of the equipment for the operators, but also safe for its environment where it is installed and safe for the utilities that will be used to operate and power the equipment.

To ensure that the combination of the electrical components we selected for our control panel designs met or exceeded the requirements set forth by the CE directives and standards, we employed the help of two third party companies to assist with testing and certification of our equipment at our factory prior to shipment to the customer.

2 Third Party Partners For Quality And Compliance Testing

1- Underwriters Laboratories

The first company we contracted with was Underwriters Laboratories, LLC. also known as UL. They are the governing body responsible for managing the UL listing that is common on electrical devices noting that they meet or exceed the local standards for use in the US. For more information on what they do and how they can help you, please visit their website at www.ul.com.

UL performed an electrical safety inspection per IEC 60204-1 on all the assemblies that we built for our customer. This testing includes:

- The grounding of all electrical devices in our control panels

- Verifying that the build and integration of the electrical controls safely operated the unit from a de-energized state to an energized state

- Controlling all hazardous energies appropriately and safely

- Confirming the safety systems integrated in our designs function properly to safely de-energize the machine

As the manufacturer of the equipment, we also need to ensure that the equipment includes all necessary labelling, warnings, and informational placards fixed to the equipment to make sure that any operator or personnel installing, working on, or operating this equipment can safely identify the potentially hazardous parts (i.e. rotating equipment, hot surfaces, loud noises) as well as verify that the electrical utilities required are within safe operating ranges.

This inspection is not meant to be the solution to any issues, but rather a source to identify any issues that we, the manufacturer, may have missed or overlooked in our designs. Fortunately, the outcome of our time with the UL group was speedy and very beneficial. We received only a few marks on our inspection, and many were items of clarifications on the operation of the equipment and non-impacting to the design or our ability to proceed with the CE compliance process.

2- ElectroMagnetic Investigations

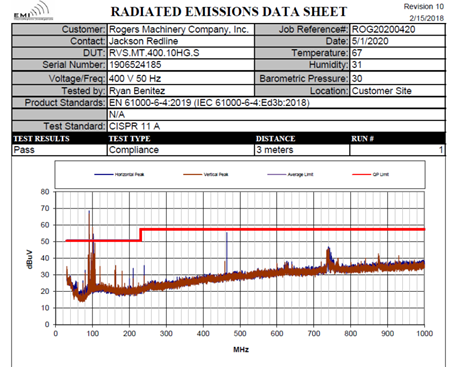

The second company that we contracted with was ElectroMagnetic Investigations (EMI) to test our compliance to the EMC directives of CE, specifically EN 61000-6-2:2019 for Heavy Industrial Equipment. EMI is an independent testing laboratory that specializes in EMC testing and safety analysis. You can find more about their company and the services they offer at www.emicomply.com.

This is a common process that almost any new electronic component on the market must go through to be accepted. Normally, the electrical components and equipment they test is small and sits well in the controlled environment of their lab. However, due to the size and weight of the vacuum pump assemblies, that was not an option, so instead they brought their lab to us.

Figure 6: EMC compatibility testing of radiated emissions of a Rogers Engineered Vacuum System.

EMC compliance testing is comprised of a series of individual tests that at the core are verifying that our equipment will not affect any other equipment that is either in the same area by radiating emissions or be affected by other equipment in the area by emissions radiated to our equipment from the surroundings.

These emissions can come in a variety of forms and from a host of sources, but predominantly they come in two ways:

- Emissions conducted through the air/space around the machine

- Emissions conducted through the power and control wiring to the machine.

When electricity runs through wiring, circuits, and any electrical device it will create a magnetic field around that energized device. As this electricity cycles (per the discussion above) this causes the polarity of the magnetic field to flip with each cycle. The changing of magnetic fields can lead to emitted energy which can vary in their own frequency or power.

Figure 7: Magnetic fields generated in wiring with current flow.

This interplay of electricity and magnetism is called electromagnetism. The magnetic fields around energized electronics can disrupt or distort other local electrical fields if they are powerful enough. These distortions are measured across a range of frequencies generated when the equipment is powered. A sample of the measured frequencies measured are below from the report generated by EMI.

Figure 8: Radiated emissions test for Arsenic House Vacuum System.

The graph shows the allowable limits across the range of frequencies in the red lines. The more critical frequencies are the higher frequencies which carry more energy and can cause disruption in nearby electrical signals like cell phone signals or wireless internet.

Generally, for air compressors and vacuum pumps, the most susceptible components to any emissions or power line surges from outside sources or even potential sources of power line surges themselves are the motors and motor control devices (i.e., variable speed drives, solid-state reduced voltage starters).

Additional Considerations

Other devices that are affected by these emissions are the PLCs which are essentially small industrial computers which can be programmed to perform a variety of tasks from controlling when to turn the lights on and off, to monitoring the vacuum level of your system, speeding up or slowing down the vacuum pump to match that capacity to control to a specific setpoint, all while monitoring different inputs like temperatures, pressures, and flows to determine if the pumps are operating correctly or if they need to be alarmed and shut down for an operator to come look at them.

Something as simple as a discharge of static electricity might be enough to fry the internals of a PLC or other sensitive electrical components

Figure 9: Electrostatic discharge testing of a Rogers Vacuum System verified that static discharges up to 8kV will not disturb our equipment operation.

All these devices are critical for operation and as such need to be verified that they will not be affected. EMI not only tests to make sure that our equipment won’t be affected but ensures that other equipment won’t be affected by ours if they are operating in the same area.

All EMC tests for the equipment were passed for all the equipment that we were providing to our customer. The reports generated by the EMC testing agency were compiled with the product data binders that were provided with the equipment for the local regulators in Europe can review them if required.

Conclusion

While making a CE compliant piece of equipment is not the same as making a CSA listed piece of equipment, there are many similarities between the two and amongst the other regulations like ETL, UL, and others.

It is critical to be aware of the differences and the impacts the different regulations may carry with them on the respective equipment. Additionally, manufacturers and customers must be aware of the differences of each region, as they may impact the utilities described above or the performance of the equipment. Read a detailed case study about that here.

Our standard is to provide our equipment with a CSA listed electrical control panels, but we don’t let that become a limiting factor in our path to supporting our customers wherever they may be. We take pride in our in-house engineering and design services and readily engage with 3rd party testing and evaluating services. Above all, we do what is right to make sure that the equipment we are providing to our customers is safe, effective, and the right choice for their specific process.

Written by Jackson Redline, Corporate Sales Engineer, Rogers Machinery.

Read more customer case studies from our Custom Process Solutions team.