Your Cart is Empty

A Guide to Selecting the Right Vacuum Pump for Your Application

This article will cover everything you need to know about choosing the best vacuum pump for your facility and application. We discuss some of the applications best suited for an oil-lubricated vs. oil-free vacuum pump, when you would want to control your system with a variable speed drive, and break down the top 6 situations a fixed speed drive for an oil-lubricated vacuum pump is best.

Estimated read time: 8 minutes

Table of Contents

- Do You Need an Oil-Free or Oil-Lubricated Vacuum Pump?

- Rogers KRVP Vacuum Features

- Variable Speed Drives 101

- Should You Operate with Fixed or Variable Speed?

Oil-lubricated rotary screw vacuum pumps have been around for many years and have provided a simple, reliable and efficient source of industrial vacuum for many industries worldwide. Variable Speed Drive (VSD) technology can be beneficial to many applications, but not all. Taking these factors into consideration is important when selecting a vacuum pump for your facility.

Key Takeaways:

- Understanding Application Requirements — it's crucial to assess whether your vacuum pump application demands variable speed or fixed speed operation to ensure optimal performance and energy efficiency.

- Energy Efficiency Considerations — Variable speed drives can offer significant energy savings in applications with fluctuating demand, whereas fixed speed pumps may be more suitable for consistent, steady-state operations.

- Equipment Longevity — Selecting the appropriate drive type can impact the lifespan of your equipment; mismatched applications may lead to increased wear and maintenance needs.

- Cost Implications — While variable speed pumps may have higher upfront costs, they can result in lower operating expenses over time in variable demand scenarios.

- Expert Consultation — Consulting with vacuum system specialists can help determine the most suitable pump type for your specific application, ensuring both performance and cost-effectiveness.

First, let’s cover oil-free versus oil-lubricated vacuum pumps.

Do You Need an Oil-Free or Oil-Lubricated Vacuum Pump?

It is important to note that processes which ingest liquids or condensing gasses that are incompatible with the lubricant are not recommended for oil-lubricated vacuum pumps. Specialized filtration can be added to reduce or eliminate these contaminants, but the cost of adding this filtration system may encourage you to consider a different technology, such as an oil-free vacuum pump.

RELATED: VACUUM FUNDAMENTALS: PROCESS APPLICATIONS AND OIL-FREE TECHNOLOGY

Operating An Efficient Oil-Lubricated Rotary Screw Vacuum Pump

Many vacuum pump technologies have a specific niche. However, many applications overlap, making selecting the right equipment potentially confusing. Understanding your plant performance needs is important in selecting the correct vacuum pump.

Best Applications for Oil-Lubricated Vacuum Technology

- Tooling hold-down tables

- Vacuum forming

- Material holding during automated processing (can and bottle making, general parts conveying or hold down)

- Food & beverage packaging

RELATED: WHEN A ROGERS KRVP OIL-LUBRICATED ROTARY SCREW VACUUM PUMP IS EXACTLY WHAT YOU NEED, THESE APPLICATIONS ARE BEST

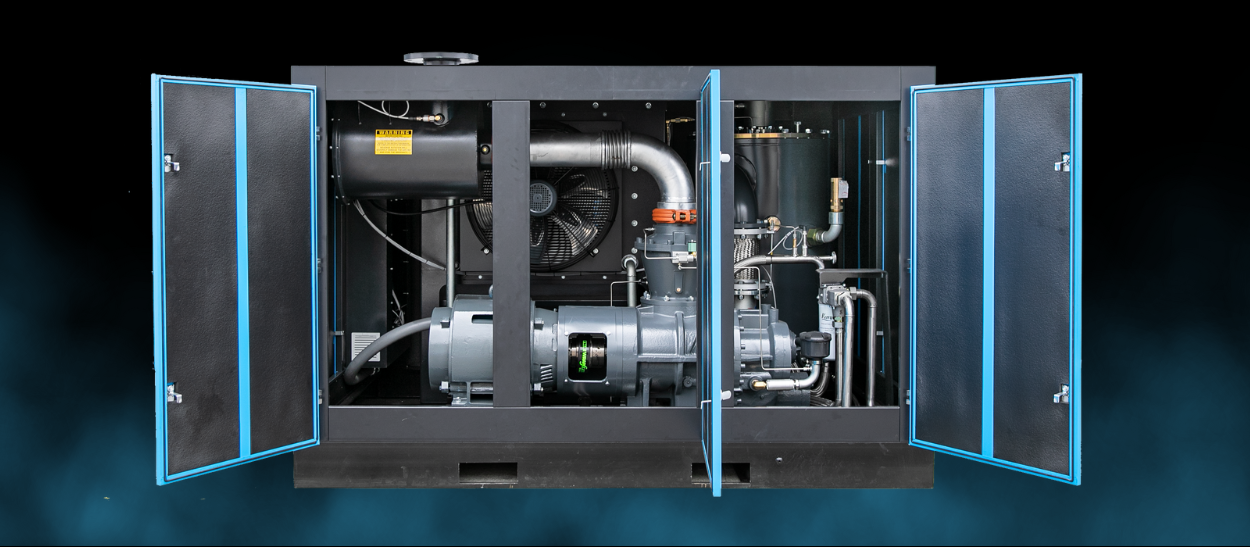

Rogers KRVP Vacuum Features

- Air and water-cooled – provides flexibility to meet your needs

- Standard with a starter or VFD – starter integrated into the package saves you time and money during install

- Modulation or VFD control – holds precise vacuum levels. In addition, the robust VFD control design allows full speed operation at all operating pressures.

- vGOAT microprocessor controller – visual indicators and a text display provides easy to read feedback and maintenance interval information

- Inlet filtration in the package – saves space and money not having to add additional filtration unless necessary.

- Economical – packaged more completely and with lower cost than typical for other technologies, so you can keep funds for other parts of your project

- High efficiency – low power consumption across the range of operation

For many vacuum pump units, components included with a lubricated rotary screw can be provided separately at additional cost, so make sure you are getting the performance and control features that will best suit the application.

RELATED: CABINET COMPANY IMPROVES RELIABILITY & PERFORMANCE BY UPGRADING TO A KRVP OIL LUBRICATED VACUUM PUMP

Variable Speed Drives 101

A variable speed drive (VSD) is an electronic device that controls the speed of an electric motor by adjusting the voltage and frequency of the power supplied to it. This allows the unit to adjust based on required load of the pump. VSDs are usually used to reduce energy consumption.

A vacuum pump without a VSD controlled main motor would be called a fixed-speed vacuum pump. The motors in fixed-speed pumps are typically Alternating Current (AC) induction motors. These motors have a base speed that is relative to the input power frequency and number of poles in the motor. On 60 Hz power, a motor with 4 poles operates at a nominal 1800 RPM. A motor with 2 poles on 60 Hz power operates at 3600 RPM.

When you couple a motor operating at a fixed speed to an oil-lubricated rotary screw vacuum pump, the volumetric flow through the vacuum pump is also fixed.

VSDs use 6 rectifiers, a DC bus and 6 IGBTs. The rectifiers and IGBTs can engage and disengage between 7,000 and 15,000 times per minute.

“Across the Line” starters utilize a solenoid to create a mechanical path of the power to the motor. The solenoid is activated once at startup and then is deactivated to stop the motor.

To keep your vacuum system working effectively, you need to match the flow and vacuum requirements of the vacuum pump to the flow requirements of the system. Using a fixed speed vacuum pump, you can either:

- Unload the vacuum pump

- Operate the vacuum pump at the lowest vacuum level it attains and modulate the inlet or use a vacuum regulator to control the system pressure

This second option can be quite attractive in the world of vacuum. As your vacuum level drops, the amount of power required actual decreases.

Energy Efficiency for Vacuum Pumps

Since the introduction of vacuum pumps, many improvements have been made to increase the efficiency of these workhorses of vacuum production. One of these improvements has been the introduction and adoption of variable speed drives (VSD) for the main motor.

This improvement has become so prevalent in the oil-lubricated rotary screw vacuum pump market that some manufacturers only sell the unites with VSD controls.

Why Would You Want To Control the Main Motor With A VSD?

Operating a VSD means power savings. Take this example:

A 50 HP air compressor requires about 45 kW of power. When running 8,000 hours a year with an electrical rate of 8 cents per kWh, the air compressor will cost $28,800 to operate. A system which requires approximately 50% of the output of a vacuum pump will require about 80-90% of the power from a fixed-speed vacuum pump (we will estimate 85% for comparison purposes).

A VSD controlled vacuum pump would require approximately 50% of the power to produce 50% of the output. This leads to 35% in savings. That 35% savings translates into $10,080 over the year.

Now that we’ve completed the crash course in VSD technology, let’s talk about the differences between oil-free versus oil-lubricated vacuum pumps.

Should you Operate with Fixed or Variable Speed?

Now you know about VSD technology, oil-free & oil-lubricated vacuum pump options, and what the KRVP is capable of. Does that mean you should always buy a variable speed driven, oil-lubricated rotary screw vacuum pump? Not always.

Here are 6 applications where a fixed-speed unit is best:

1: Hot and/or Dirty Environments

Precise electronics do not like heat and dirt. If dust gets into the wrong place, the VSD can short circuit and the vacuum pump will stop working.

To dissipate the 3-5% of the total power that is generated by a VSD in heat, you need to have cool air and consistent air flow. Most VSDs have fans with filters that provide air flow to cool the VSD, but those aren’t as effective if the air is already hot and if the filters are plugged with dust.

While Rogers Machinery can provide special packaging or a remote located VSD which can help prolong the VSD life, that isn’t an option with all manufacturers. If you don’t want to pay the extra cost for special packaging, a fixed speed unit may be the right choice.

2: No Redundancy or a Critical Application

It is always recommended to have redundancy in a vacuum or compressed air system. However, sometimes that just isn’t possible or practical. A VSD-controlled vacuum pump has the opportunity for power savings, but VSDs do not have the high life expectancy of the other major components in your vacuum pump.

Typical motor or airend issues are preceded by heat or noise, which can allow a plan to be implemented before the unit fails. VSDs don’t provide this type of feedback.

Critical applications may also not be candidates for VSD-controlled vacuum pumps, where losing a VSD and shutting down your process can cause you to scrap a batch of product hurting your bottom line. Depending on your manufacturer, you may have to wait for a proprietary VSD, which may require special programming, tuning and troubleshooting. Other types of starters can typically be sourced from any electrical supply company and can be plug and play.

3: System Requirements are for Greater than 95% of the Vacuum Pump Output

As previously mentioned, VSDs are effective at reducing power when operating at partial loads. However, 3-5% of the energy going into a VSD is lost to inefficiencies, mainly in heat. Therefore, if you have a process in which the VSD is going to be operating at over 95-97% load, then the VSD will actually be using more power for a similar flow.

4: Short Duty Cycles

The savings in utilizing a VSD are in the power consumption. Let’s refer to the earlier example of the power for a 50 HP compressor costing about $28,800 per year: one of the keys to the assumed savings of a VSD operated vacuum pump is the operating hours. If you are only operating one 8-hour shift, the $10,080 in savings drops to one third or $3,360 per year.

The cost of replacing a VSD can easily exceed 25-50% of the initial purchase, and that might show that the savings in electricity will actually cost you more in VSD replacements over the long run. Ask your vacuum pump supplier what a replacement VSD would cost and compare that to your electrical savings. The math may say that the VSD savings aren’t there.

5: Pump Down Applications

In most typical pump-down applications, you want to get the process to the appropriate vacuum level as fast as possible so that you can complete your batch and move on to the next one. Unfortunately, most VSD-controlled vacuum pumps can’t operate at maximum output from atmospheric pressure at the beginning of the pump-down process and can slow you down.

With a patented flexible discharge port, Rogers KRVP vacuum pumps can operate at full flow from initial atmospheric pressure all the way down to your system pressure requirements.

6: Systems with Multiple Vacuum Pumps

For systems of multiple vacuum pumps, using one or two VSD-controlled vacuum pumps to trim the demand alongside a group of fixed-speed vacuum pumps combines the energy efficiency of VSD control with the reliability of the fixed speed units. This may ultimately also provide a more efficient system. Rogers Machinery KRVP vacuum pumps are available with VSD or fixed speed motor control and can be combined to best fit your application.

RELATED: VACUUM FUNDAMENTALS: UTILITY APPLICATIONS AND OIL SEALED TECHNOLOGY

VSD-controlled oil-lubricated rotary screw vacuum pumps provide the opportunity to save power costs but are not right for all applications. By knowing what your facility needs, you’ll be able to assess the variables in selecting the right vacuum pump for your application.

Meet the Contributor

|

Jackson Redline is a mechanical engineer and project manager working in the Engineered System Solutions team. Jackson started at Rogers Machinery fresh out of college and was recently recognized in Plant Engineering 2023 Leaders under 40. |