Your Cart is Empty

Engineered System Solutions

Rogers Machinery News is your place for informative, educational articles and case studies about air compressors, pumps, blowers & vacuum systems. Our goal is to provide useful information that will help you make informed product decisions – all to keep your facilities running efficiently with maximum uptime.

9 news articles

Liquids and Vacuum - Considerations & Best Practices

Vacuum systems play a critical role in a wide range of industrial applications, particularly where liquids are involved. Understanding how liquids behave under vacuum and how to optimize system performance is essential for efficiency, safety, and reliability. This article explores key considerations and best practices for working with liquids in vacuum environments.

Written by Jackson Redline

Implementing Vacuum System Innovations in the Real World: How Installation Location & Weather Affect Performance and System Design

High and low atmospheric pressures affect vacuum systems. But how much? In this article, vacuum expert Bryan A. Jensen covers how weather systems on our planet affect vacuum systems and how each type of vacuum usage — utility vacuum or process vacuum — responds to barometric changes in our atmosphere.

Organic Valley Keeping Local

In replacing the antiquated vacuum equipment with an energy efficient whole system solution, Organic Valley was able to save approximately 32,000 kWHrs and 16,000 gallons of water usage per year.

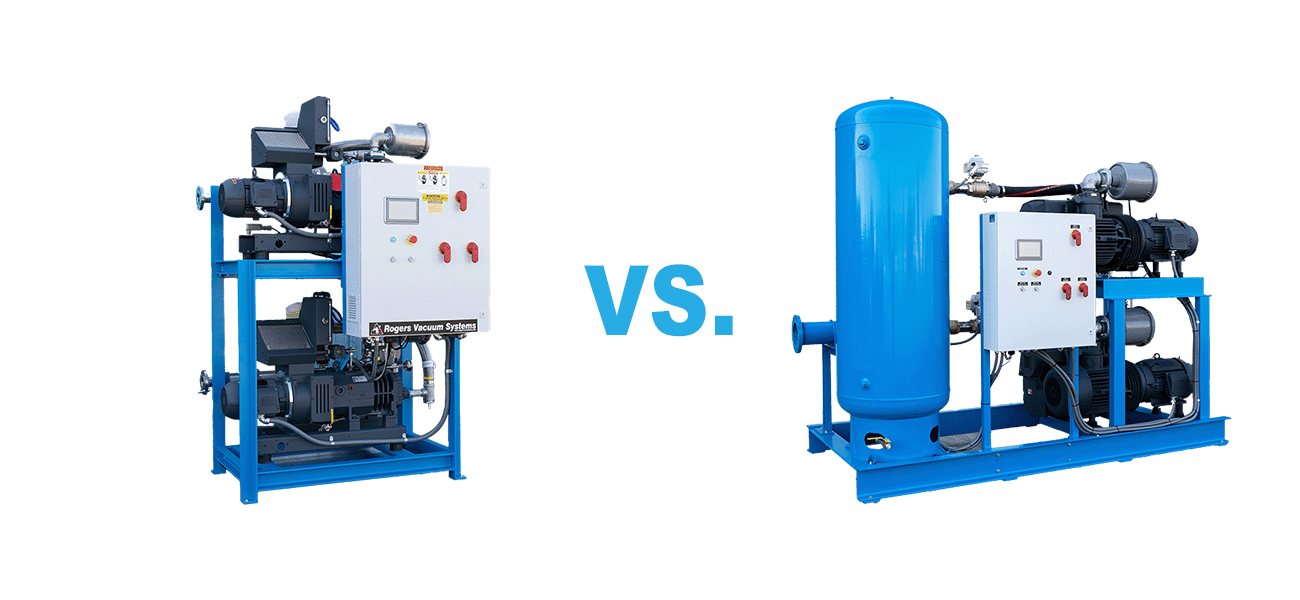

Vacuum Receivers: Full of Vacuum or Full of Myth?

In this article, we’ll discuss some of the uses for receiver tanks for positive pressure systems where the pressure inside the system is greater than atmospheric pressure, and the uses, or lack thereof of, receiver tanks in vacuum systems where the system pressure is less than atmospheric pressure.

Vacuum Thermodynamics in Our Freeze-Dried Universe

Freeze dry systems are some of the more thermodynamically active vacuum applications around, with operating pressure requirements firmly categorized in the “medium vacuum” realm. The lessons learned from the principles and subsystems in play can and should be applied broadly; to your own industrial vacuum system whether freeze-drying is your game or not; and, just maybe, in appreciation of the happenstance of our own humanity.

Written by: Bryan A. Jensen

Process Vacuum Applications & Oil-Free Technology

In this article, we dive into the differences between utility and process vacuum, measurement guidelines, and specifying vacuum systems to process applications for maximum system efficiency.

Written by: Bryan A. Jensen

Utility Vacuum Applications and Oil Sealed Technology

In this article, we define the fundamentals of vacuum and discuss utility applications of oil-sealed vacuum technology.

Written by: Bryan A. Jensen

Supporting Customers Internationally With Engineered System Solutions

When a high-tech electronics customer came to us for a vacuum system solution at their Ireland plant, we took on the unique and challenging project taking steps to ensure the system met EU standards without sacrificing performance.

High-Tech Electronics Customer Gets A 'Boost' To Vacuum Performance Saving Over $200K In Energy & Water Costs

Before we get into the nitty gritty, here are the broad strokes of a project we completed recently in New Mexico. As you’ll see, it started out with a common problem which all facility engineers and operators face...