Your Cart is Empty

Viking Pump - API Compliant Pumps

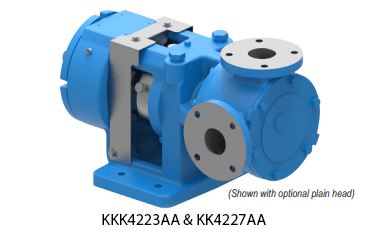

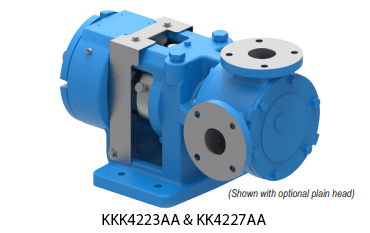

4223AA, 4323AA & 4227AA Series pumps offer all of the features, benefits and options of the Universal Product Line pumps with steel externals construction, but feature a larger bracket that enables the use of API 682-compliant cartridge seals.

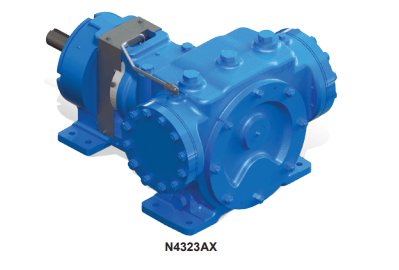

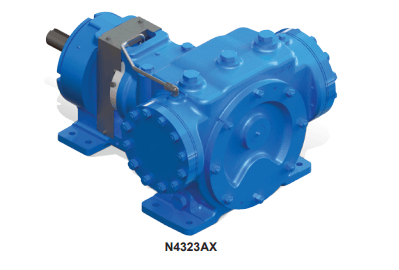

4223AX & 4323AX Series foot-mounted internal gear pumps are designed and manufactured to comply fully with the current version of the American Petroleum Institute’s design standard for positive displacement pumps, API 676.

- Capacity 15 – 1600GPM

- Viscosity 28-35,000 SSU

- Pressure to 200PSI

- Temperature to -20F to 550F

Materials:

4223AA, 4323AA, 4223AX & 4323AA: Cast Iron

4227AA: Stainless Steel

-

This product price is available on request only

Product details

These pump series from Viking Pump were specifically designed to be in conformance with API’s 100+ page specification on everything from design of pressure containing parts, bearing life, Non-Destructive Examination, to mounting foot flatness. Ensuring the most robust pump possible. Full compliance reduces risk and simplifies project specs by eliminating sign-offs necessary on non-compliant equipment.

-

- API 682 Seal. Viking’s seal chamber will accept almost any customer-specified brands and types of API 682-compliant Category 1, 2 or 3 cartridge mechanical seals, and can provide API seal plans to meet application requirements. Standard seal is a category 2 single mechanical seal. Carbon vs. silicon carbide with API Plan 13.

- 3mm corrosion allowance above Maximum Allowable Working Pressure (MAWP). The XPD 676 has an additional 3mm corrosion allowance built into all pressure containing components over and above our standard steel Universal Seal series pumps.

- 25,000 hour L-10 life on tapered roller bearings. Standard on all sizes at maximum speed and pressure.

- Steel castings to be normalized and tempered. Standard. • High Strength Bolting. XPD 676 features high strength fasteners stamped with manufacturer’s symbol and material codes, studs on some sizes. Threaded holes are drilled and tapped to minimum 1.5X stud diameter with minimum metal around the bottom of threaded holes at least 0.5X stud diameter plus 3mm corrosion allowance, per the specification.

- Casing drain and seal chamber vent. XPD 676 has cast-in casing drain with ANSI Class 300 RF flange and seal chamber vent to completely drain the casing before maintenance.

- Mounting surfaces flat and parallel. The mounting feet of XPD 676 pumps are machined to 6.3µm Ra, with flatness tolerance of 25µm. The upper surface is machined parallel to the foot, and where the pump has both bracket and casing feet (N & R sizes), the feet are machined flat and parallel, in the same plane within 150 µm/m (0.002 in./ft) of distance between the mounting surfaces after the pump is assembled.

- Rectangular keyways. Viking cuts rectangular keyways with required fillets and includes the key with each pump. Tapered shaft extension on shafts larger than 2.5”. Viking tapers the shaft extension on the “R” size for easy removal of the coupling half.

- Non-Destructive Evaluation of castings and post-weld evaluation of any necessary weld repairs using mag particle (MT) testing

- Certified hydrostatic testing to 1.5X MACP

- Certified performance testing in accordance with Section 3.6 of the Hydraulic Institute pump standards, at the specified viscosity (from 28 to 25,000 SSU), with data including speed, discharge pressure, suction pressure, power, and capacity. Viking XPD 676 pumps carry a five year limited warranty.

- Packaging for long term storage, including corrosion inhibitor applied to exposed metal parts and metal port covers to protect internals from corrosion and contaminants.

- Documentation to include, at a minimum:

- Certified dimensional outline drawing

- Allowable flange loadings • Cross-sectional drawing and bill of material

- Mechanical seal drawing & bill of material

- Performance curve

- Certified hydrostatic test data

- Material certifications (traceability)

- Weld procedure specification (WPS

- Weld maps

- Non-destructive testing procedures

- Performance test procedures

- Performance test data

- Data sheets applicable to proposals, purchase & as-built • Installation manual • Operation & Maintenance manual • Spare parts recommendations & price list • List of drawings & submittals

- Shipping list

- There are many more requirements of the API 676 specification, and Viking has designed this pump to comply with all of them, as standard.

Features & Benefits

Besides the features required by the API 676 standard, Viking offers many additional features and benefits that our customers commonly request, including:

- Jacketing to melt ambient-temperature solids like bitumen before startup. The XPD 676 features jacketed bracket and casing as standard, with option for jacketed head.

- Opposite ports with reversible direction of flow are standard, for easy in-line piping and the ability to transfer product in either direction or strip a line of product.

- O-Ring seals on head and casing joints instead of gaskets for maximum sealing effectiveness

- Optional labyrinth seals on bearing housing for longest bearing life by minimizing contamination (lip seals standard).

- Grease lubrication standard, enabling re-greasing of pump during operation, without the need for shutdown.

- End clearance is easily adjusted to compensate for wear over time or for higher temperatures or viscosities, by simply rotating the threaded bearing housing.

-

- Description

- API 682 Seal. Viking’s seal chamber will accept almost any customer-specified brands and types of API 682-compliant Category 1, 2 or 3 cartridge mechanical seals, and can provide API seal plans to meet application requirements. Standard seal is a category 2 single mechanical seal. Carbon vs. silicon carbide with API Plan 13.

- 3mm corrosion allowance above Maximum Allowable Working Pressure (MAWP). The XPD 676 has an additional 3mm corrosion allowance built into all pressure containing components over and above our standard steel Universal Seal series pumps.

- 25,000 hour L-10 life on tapered roller bearings. Standard on all sizes at maximum speed and pressure.

- Steel castings to be normalized and tempered. Standard. • High Strength Bolting. XPD 676 features high strength fasteners stamped with manufacturer’s symbol and material codes, studs on some sizes. Threaded holes are drilled and tapped to minimum 1.5X stud diameter with minimum metal around the bottom of threaded holes at least 0.5X stud diameter plus 3mm corrosion allowance, per the specification.

- Casing drain and seal chamber vent. XPD 676 has cast-in casing drain with ANSI Class 300 RF flange and seal chamber vent to completely drain the casing before maintenance.

- Mounting surfaces flat and parallel. The mounting feet of XPD 676 pumps are machined to 6.3µm Ra, with flatness tolerance of 25µm. The upper surface is machined parallel to the foot, and where the pump has both bracket and casing feet (N & R sizes), the feet are machined flat and parallel, in the same plane within 150 µm/m (0.002 in./ft) of distance between the mounting surfaces after the pump is assembled.

- Rectangular keyways. Viking cuts rectangular keyways with required fillets and includes the key with each pump. Tapered shaft extension on shafts larger than 2.5”. Viking tapers the shaft extension on the “R” size for easy removal of the coupling half.

- Non-Destructive Evaluation of castings and post-weld evaluation of any necessary weld repairs using mag particle (MT) testing

- Certified hydrostatic testing to 1.5X MACP

- Certified performance testing in accordance with Section 3.6 of the Hydraulic Institute pump standards, at the specified viscosity (from 28 to 25,000 SSU), with data including speed, discharge pressure, suction pressure, power, and capacity. Viking XPD 676 pumps carry a five year limited warranty.

- Packaging for long term storage, including corrosion inhibitor applied to exposed metal parts and metal port covers to protect internals from corrosion and contaminants.

- Documentation to include, at a minimum:

- Certified dimensional outline drawing

- Allowable flange loadings • Cross-sectional drawing and bill of material

- Mechanical seal drawing & bill of material

- Performance curve

- Certified hydrostatic test data

- Material certifications (traceability)

- Weld procedure specification (WPS

- Weld maps

- Non-destructive testing procedures

- Performance test procedures

- Performance test data

- Data sheets applicable to proposals, purchase & as-built • Installation manual • Operation & Maintenance manual • Spare parts recommendations & price list • List of drawings & submittals

- Shipping list

- There are many more requirements of the API 676 specification, and Viking has designed this pump to comply with all of them, as standard.

Features & Benefits

Besides the features required by the API 676 standard, Viking offers many additional features and benefits that our customers commonly request, including:

- Jacketing to melt ambient-temperature solids like bitumen before startup. The XPD 676 features jacketed bracket and casing as standard, with option for jacketed head.

- Opposite ports with reversible direction of flow are standard, for easy in-line piping and the ability to transfer product in either direction or strip a line of product.

- O-Ring seals on head and casing joints instead of gaskets for maximum sealing effectiveness

- Optional labyrinth seals on bearing housing for longest bearing life by minimizing contamination (lip seals standard).

- Grease lubrication standard, enabling re-greasing of pump during operation, without the need for shutdown.

- End clearance is easily adjusted to compensate for wear over time or for higher temperatures or viscosities, by simply rotating the threaded bearing housing.

- Specifications

- Resources

- Brochures

Rent product

Interested in renting Viking Pump - API Compliant Pumps? Please fill in the form below and we will get back to you in the shortest time.

{formbuilder:86391}