Your Cart is Empty

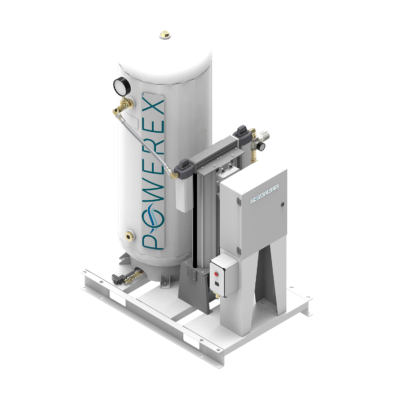

Powerex - Air Treatment Package

The TDD Industrial air treatment skid is engineered to provide clean and dry compressed air at a low dew point rated for -40°F. The TDD package is ideal for critical process applications that require moisture-free compressed air such as instrument air systems, food packaging and processing applications to prevent contamination and spoilage, and pharmaceutical manufacturing where dry compressed air is vital to maintain high purity and quality.

- Medical air quality

-

This product price is available on request only

Product details

Powerex provides market leading medical air piping systems.

-

Energy Efficiency The -40°F Desiccant Dryer is built with energy efficiency in mind. The system is equipped with advanced controls that optimize the drying process, minimizing energy consumption while still maintaining outstanding moisture removal capabilities. System Features • Regenerative Desiccant Process: this drying system employs a regenerative process, utilizing adsorbent desiccant material to capture and hold moisture. The desiccant is then regenerated, allowing the dryer to continue delivering consistent and efficient drying performance.

• Energy Efficient: the desiccant dryer is built with energy efficiency in mind. The system is equipped with advanced controls that optimize the drying process, minimizing energy consumption while still maintaining outstanding moisture removal capabilities.

• Low Maintenance: the dryer is engineered for long-term reliability and requires minimal maintenance, reducing downtime and overall operational costs.

Available Options • -94°F

• Additional Carbon Filter

• NEMA4 Control Panel

-

Base Model Tank Size Dryer Size SCFM Inlet/Outlet Weight (lbs) TDD080030 80 30 3/4" 450 TDD120045 120 45 3/4" 585 TDD120060 120 60 1" 601 TDD200100 200 100 1" 1100 TDD240125 240 125 1" 1400 TDD240200 240 200 1"-1/2" 1400

- Description

Energy Efficiency The -40°F Desiccant Dryer is built with energy efficiency in mind. The system is equipped with advanced controls that optimize the drying process, minimizing energy consumption while still maintaining outstanding moisture removal capabilities. System Features • Regenerative Desiccant Process: this drying system employs a regenerative process, utilizing adsorbent desiccant material to capture and hold moisture. The desiccant is then regenerated, allowing the dryer to continue delivering consistent and efficient drying performance.

• Energy Efficient: the desiccant dryer is built with energy efficiency in mind. The system is equipped with advanced controls that optimize the drying process, minimizing energy consumption while still maintaining outstanding moisture removal capabilities.

• Low Maintenance: the dryer is engineered for long-term reliability and requires minimal maintenance, reducing downtime and overall operational costs.

Available Options • -94°F

• Additional Carbon Filter

• NEMA4 Control Panel

- Specifications

Base Model Tank Size Dryer Size SCFM Inlet/Outlet Weight (lbs) TDD080030 80 30 3/4" 450 TDD120045 120 45 3/4" 585 TDD120060 120 60 1" 601 TDD200100 200 100 1" 1100 TDD240125 240 125 1" 1400 TDD240200 240 200 1"-1/2" 1400 - Brochures

Rent product

Interested in renting Powerex - Air Treatment Package? Please fill in the form below and we will get back to you in the shortest time.

{formbuilder:10226}