Your Cart is Empty

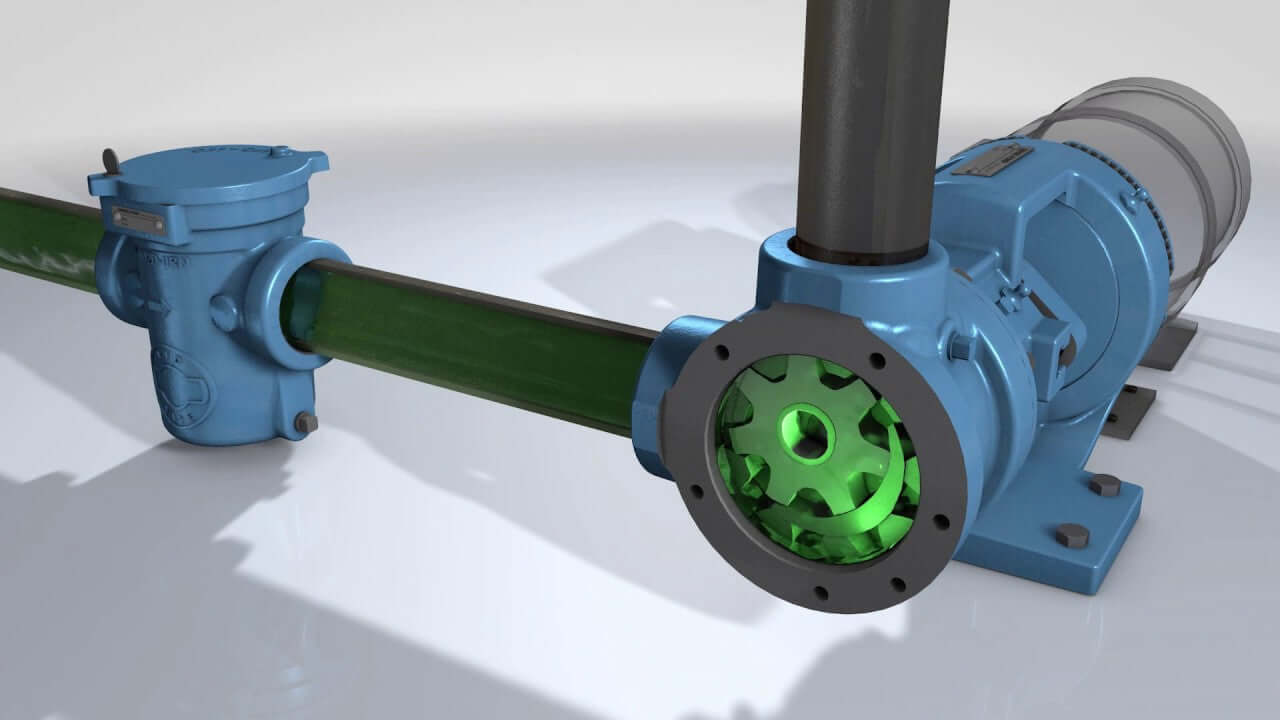

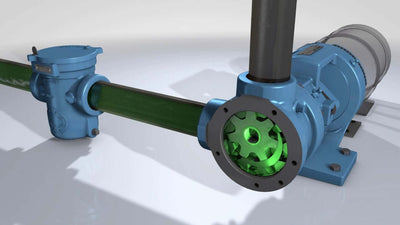

Viking Pump - Simplex Pump Strainers

Viking Simplex Strainers provide protection for your pumping system with low-pressure drop.

- Capacity 20 – 1500GPM

- Micron 140 - 1910

- Pressure 125 to 640

- Temperature to -40F to 400F

-

This product price is available on request only

Product details

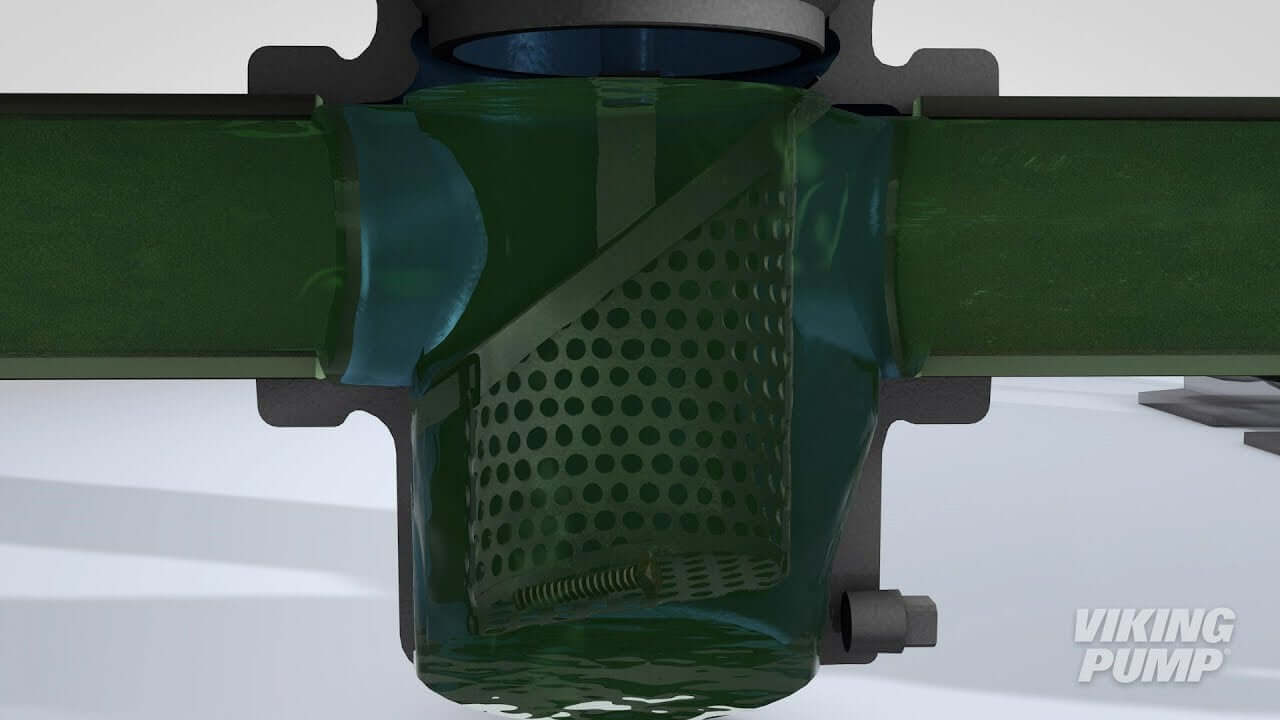

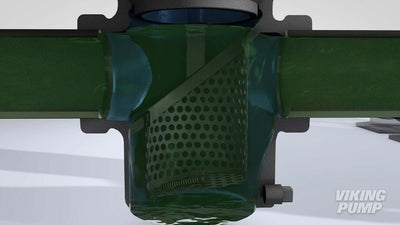

Simplex Strainers provide protection for your pumping system with low pressure drop. The inclined position of the strainer basket adjacent to the porting provides smooth flow patterns not found in conventional basket-type strainers. Viking’s Lid-Ease Simplex Strainers reduce cleaning problems encountered with conventional strainers. Simple lid rotation disengages the breech lock type lid permitting easy removal of the basket. Basket is removed from the top of the strainer, possibly eliminating the need to completely drain the system or allowing foreign matter to drop back into the line when the strainer is cleaned. The relatively small port-to-port dimensions of the strainer allow easy installation. Viking Lid-Ease Simplex Strainers are designed with a weatherseal lid to protect the breech lock area from exterior elements and prevent air infiltration into the pump suction. Strainers are also equipped with a drain plug for complete draining of strainer if needed. Tapped or flanged end ports available

-

Lid-Ease Simplex Strainer

FEATURES & BENEFITS

- Quarter-turn, easy opening breech-lock lid simplifies routine cleaning

- Inclined basket design provides low pressure drop for high system efficiency

- Top basket removal eliminates the need to drain the strainer and minimizes product loss

- High-quality, easy-to-clean simplex strainers

- Designed for chemical, petrochemical and most general fluid-flow applications

- Tapped or flanged porting are available for ¾, 1, 1½, 2, 3, 4, 6 and 8 inch piping

- SS basket and screen are available in no mesh, 10, 20, 40, 60, 80 or 100 mesh

- Nominal capacities range from 20 to 1,500 GPM

- Pressures up to 200 PSI

- Strainer bodies & lids are available in cast iron or stainless steel

OPTIONS

- Basket mesh from 10 to 100

- Magnetic inserts for trapping ferrous particles

- Differential pressure indicators optimize cleaning intervals

LOW PRESSURE DROP

Viking Lid-Ease Strainers are designed for minimal pressure drop through the unit.

Pressure drop is minimized by the inclined position of the strainer basket adjacent to the porting.

This provides smooth flow patterns not found in conventional basket type strainers.

EASY TO CLEAN

No special tools are needed for lid removal. A simple lid rotation disengages the breech-lock lid to permit easy removal of the basket. The basket is removed from the top of the strainer to eliminate foreign matter from dropping back into the line when the strainer is cleaned. The strainers are equipped with a drain plug for complete draining, if required. The light-weight and small overall dimensions make it possible to install Viking Lid-Ease Line Strainers in systems that cannot accommodate larger strainers of equal porting size.

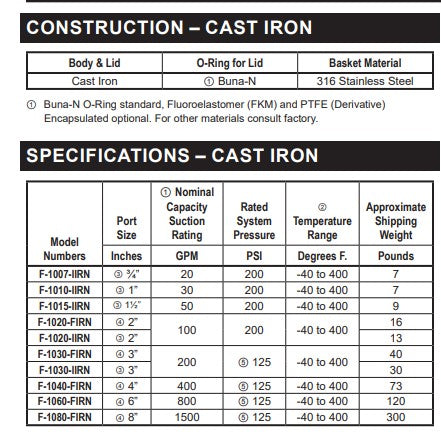

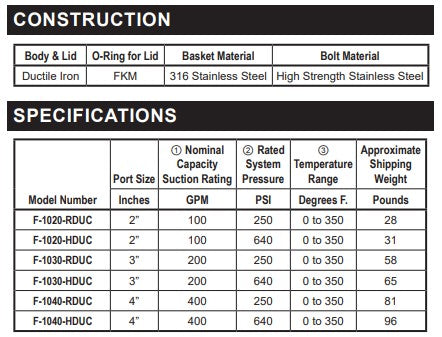

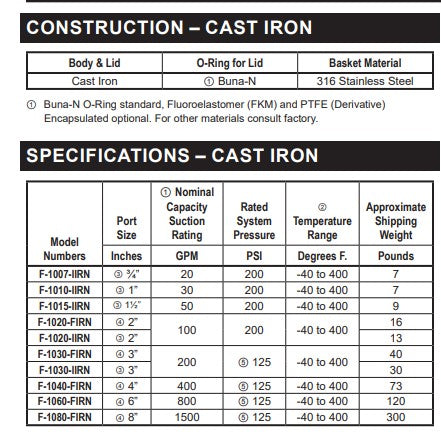

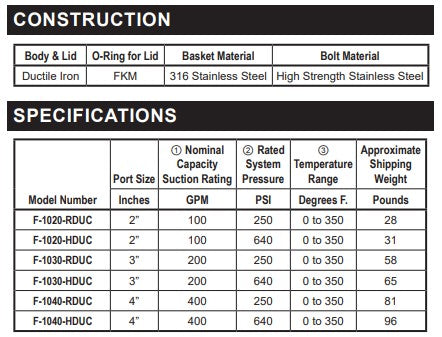

Bolted Lid Strainer

FEATURES & BENEFITS

- Strainer bodies available in ductile iron

- Lid vent, pressure differential gauge ports, and bottom drain are all standard

- Stainless steel baskets with 3/16” perforation holes standard (no mesh) • Basket lining available in 10, 20, 40, 60, 80 or 100 mesh

- Baskets provide maximum hoop strength to prevent distortion or basket damage

- Ductile iron can be used for steel requirements in chemical, petrochemical and pharmaceutical industries

- High-quality, easy-to-clean simplex strainers

- Designed for chemical, petrochemical and most general fluid-flow applications

- Raised face flanges available for 2, 3 & 4 inch piping

- SS basket and screen are available in no mesh, 10, 20, 40, 60, 80 or 100 mesh

- Nominal capacities range from 100 to 400 GPM

- Pressures up to 640 PSI

- Strainer bodies and lids are available in ductile iron

OPTIONS

- Basket mesh from 10 to 100

- Magnetic inserts

- Differential pressure indicators

LOW PRESSURE DROP

Viking Bolted-Lid Strainers are designed for minimal pressure drop through the unit. Pressure drop is minimized by the inclined position of the strainer basket adjacent to the porting. This provides smooth flow patterns not found in conventional basket type strainers.

EASY TO CLEAN

No special tools are needed for lid removal. Once bolts are removed with a standard wrench, lid is lifted to open the cover. The basket is removed from the top of the strainer to eliminate foreign matter from dropping back into the line when the strainer is cleaned. These strainers are equipped with a bottom drain plug for complete draining.

- SPECIFICATIONS – STAINLESS STEEL

Lid-Ease Simplex Strainer

Bolted Lid Strainer

- Description

Lid-Ease Simplex Strainer

FEATURES & BENEFITS

- Quarter-turn, easy opening breech-lock lid simplifies routine cleaning

- Inclined basket design provides low pressure drop for high system efficiency

- Top basket removal eliminates the need to drain the strainer and minimizes product loss

- High-quality, easy-to-clean simplex strainers

- Designed for chemical, petrochemical and most general fluid-flow applications

- Tapped or flanged porting are available for ¾, 1, 1½, 2, 3, 4, 6 and 8 inch piping

- SS basket and screen are available in no mesh, 10, 20, 40, 60, 80 or 100 mesh

- Nominal capacities range from 20 to 1,500 GPM

- Pressures up to 200 PSI

- Strainer bodies & lids are available in cast iron or stainless steel

OPTIONS

- Basket mesh from 10 to 100

- Magnetic inserts for trapping ferrous particles

- Differential pressure indicators optimize cleaning intervals

LOW PRESSURE DROP

Viking Lid-Ease Strainers are designed for minimal pressure drop through the unit.

Pressure drop is minimized by the inclined position of the strainer basket adjacent to the porting.

This provides smooth flow patterns not found in conventional basket type strainers.

EASY TO CLEAN

No special tools are needed for lid removal. A simple lid rotation disengages the breech-lock lid to permit easy removal of the basket. The basket is removed from the top of the strainer to eliminate foreign matter from dropping back into the line when the strainer is cleaned. The strainers are equipped with a drain plug for complete draining, if required. The light-weight and small overall dimensions make it possible to install Viking Lid-Ease Line Strainers in systems that cannot accommodate larger strainers of equal porting size.

Bolted Lid Strainer

FEATURES & BENEFITS

- Strainer bodies available in ductile iron

- Lid vent, pressure differential gauge ports, and bottom drain are all standard

- Stainless steel baskets with 3/16” perforation holes standard (no mesh) • Basket lining available in 10, 20, 40, 60, 80 or 100 mesh

- Baskets provide maximum hoop strength to prevent distortion or basket damage

- Ductile iron can be used for steel requirements in chemical, petrochemical and pharmaceutical industries

- High-quality, easy-to-clean simplex strainers

- Designed for chemical, petrochemical and most general fluid-flow applications

- Raised face flanges available for 2, 3 & 4 inch piping

- SS basket and screen are available in no mesh, 10, 20, 40, 60, 80 or 100 mesh

- Nominal capacities range from 100 to 400 GPM

- Pressures up to 640 PSI

- Strainer bodies and lids are available in ductile iron

OPTIONS

- Basket mesh from 10 to 100

- Magnetic inserts

- Differential pressure indicators

LOW PRESSURE DROP

Viking Bolted-Lid Strainers are designed for minimal pressure drop through the unit. Pressure drop is minimized by the inclined position of the strainer basket adjacent to the porting. This provides smooth flow patterns not found in conventional basket type strainers.

EASY TO CLEAN

No special tools are needed for lid removal. Once bolts are removed with a standard wrench, lid is lifted to open the cover. The basket is removed from the top of the strainer to eliminate foreign matter from dropping back into the line when the strainer is cleaned. These strainers are equipped with a bottom drain plug for complete draining.

- Specifications

- SPECIFICATIONS – STAINLESS STEEL

Lid-Ease Simplex Strainer

Bolted Lid Strainer

- Resources

- Videos

Rent product

Interested in renting Viking Pump - Simplex Pump Strainers? Please fill in the form below and we will get back to you in the shortest time.

{formbuilder:86391}