Your Cart is Empty

Complete Guide To On-Site Nitrogen Generation Systems And Benefits

Nitrogen gas is used in numerous manufacturing applications, including beer production, and is critical for product quality. This guide will walk you through how nitrogen generators work, the benefits, sizing considerations, costs and more.

Table of Contents

- How Do Nitrogen Generators Work?

- Do You Need Nitrogen in Beer Production?

- What Processes Use Nitrogen in Beer Production?

- 10 Key Benefits of an On-Site PSA Nitrogen Generation System

- Nitrogen Generator Typical System Layout & Safety

- Sizing a Nitrogen Generation System

- Cost of a Nitrogen Generation System

- Switching from CO2 to an On-Site Nitrogen Generation System

Key Takeaways

- Cost Efficiency: On-site nitrogen generation significantly reduces expenses associated with purchasing, transporting, and storing liquid nitrogen, leading to substantial long-term savings.

- Enhanced Safety: Producing nitrogen on-site minimizes the risks linked to handling high-pressure cylinders and cryogenic liquids, creating a safer working environment.

- Continuous Supply: On-site systems provide a consistent and uninterrupted nitrogen supply, eliminating downtime caused by delivery delays or supply shortages.

- Purity Control: Users can tailor nitrogen purity levels to meet specific application requirements, ensuring optimal performance across various industries.

- Environmental Benefits: By reducing the need for transportation and storage of nitrogen, on-site generation lowers carbon emissions and contributes to more sustainable operations.

How Do Nitrogen Generators Work?

There are 2 main technologies for Nitrogen generation: Membrane and Pressure Swing Adsorption (PSA). This article will focus on PSA nitrogen generators as a preferred technology, with specific examples for beer production. PSA nitrogen generators separate nitrogen molecules from other molecules by trapping oxygen and other gases from the compressed air stream through the process of adsorption.

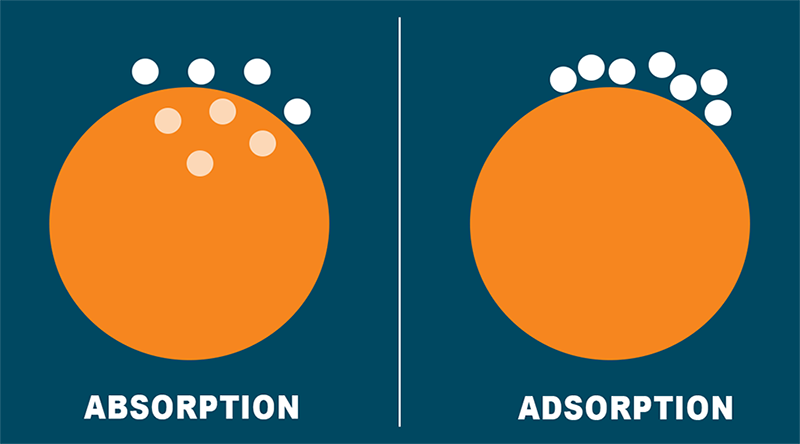

Now to quickly differentiate absorption vs adsorption, absorption is when one substance is taken inside another, like a sponge soaking up water. Adsorption is where molecules are attracted to the surface of another. In the case of PSA nitrogen generators, oxygen molecules are retained on the surface of the carbon molecular sieve. The attraction is due to a difference in pressure, and the pores in the carbon molecular sieve are just the right size for the oxygen molecules to fit in.

Do You Need Nitrogen In Beer Production?

Traditionally, CO2 was used as a natural by-product of the beer fermentation process. However, not enough was released in the fermenting process to supply the demand for modern beer production. Having tanks pre-purchased and shipped in, creates waste in unused CO2, increased production costs, and logistical and lead time issues with deliveries.

One of our customers in the brewing industry was upgrading their canning line. Here is what they had to say about CO2:

“Co2 was an increasingly difficult resource to get and trying to increase the amount of Co2 wasn’t supportive of a high quality and fast canning line.” – Khris Lloyd, Procurement Manager, Reuben’s Brews

Enter Nitrogen. Nitrogen makes up 78% of the atmosphere making it readily available, cost-effective, and with an on-site nitrogen generation system, provides a reliable and steady supply to the production and packaging process.

What Processes Use Nitrogen In Beer Production?

When quality is king, Nitrogen is the way to go. Nitrogen as a molecule isn’t as readily absorbed into the beer as CO2 is. This results in smaller bubbles creating a smoother, richer palette texture in the beer.

Nitrogen and CO2 are both used in the beer production process, however, aside from carbonation requirements, Nitrogen can effectively replace CO2 in all brewery production processes. These processes include:

- Purging tanks between batches

- Transferring beer between tanks

- Moving the beer through filtration

- Storage tank pressurization

- Blanketing tanks

- Kegging and bottling

As with all food and beverage manufacturers, nitrogen for breweries must comply with European and global standards for food grade nitrogen to prevent oxygen contamination. Nitrogen generators provide you with the flexibility to set your purity rating to meet production requirements and produce the highest quality product.

10 Key Benefits Of An On-Site PSA Nitrogen Generation System

Aside from producing a superior beer product, there are 10 key benefits of an on-site PSA nitrogen generation system:

- Energy efficient – Onsite PSA nitrogen generators have low energy consumption providing operation savings, and can be set to supply the exact demand and purity rating your production needs, no more, no less.

- Low maintenance costs

- Easy to install

- Compact – These systems are packaged to save valuable floor space.

- Safety – Eliminate the use of high-pressure tanks! Unused liquid nitrogen in tanks will expand in ambient heat causing pressure to build which can cause the tanks to explode.

- The process of on-site nitrogen generation through PSA technologies uses no chemicals, significantly lowering annual consumable costs.

- Limits waste – To prevent the risk of exploding tanks, gas must be released which wastes unused nitrogen, time, and money. On site nitrogen produces the supply you need, at the purity you need, without throwing away, or returning to a supplier, unused gas.

- Saves time – No CO2 delivery nightmares dealing with logistics, delays, lead times or even cancellations. The need to manually remove old canisters and replace them is a thing of the past.

- Reliable – Take advantage of a readily available, naturally occurring gas (it’s makes up 78% of our atmosphere!) as supply chain shortages make CO2 increasingly hard to get, and unlike the membrane technology, PSA generators produce a purity rating of up to 99.99% reliably meeting quality requirements as well.

- Environmentally friendly – On-site nitrogen generation eliminates transportation emissions with deliveries, and significantly reduces gas requirements.

Nitrogen Generator Typical System Layout & Safety

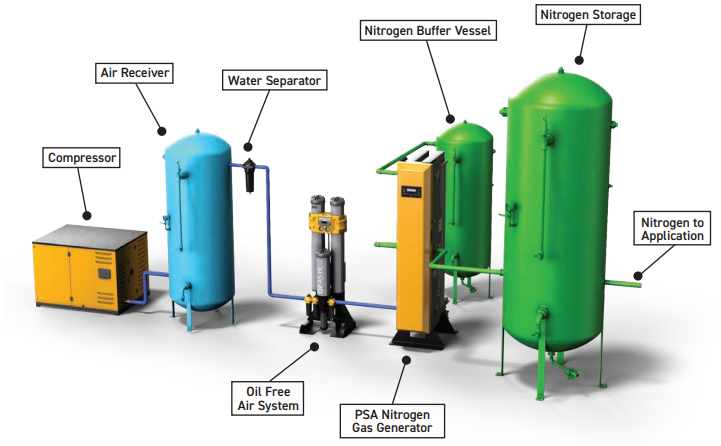

A typical nitrogen generation system layout consists of the following components:

- Air Compressor - An air compressor is used to compress air from the atmosphere to high pressure, which will then be processed to produce nitrogen.

- Pre-treatment Unit - The compressed air is filtered and dried in a pre-treatment unit to remove moisture and impurities.

- Nitrogen Membrane Unit - The dried compressed air is then passed through a nitrogen membrane unit, which consists of a bundle of hollow fiber membranes. The nitrogen molecules are separated from the other gases due to their smaller size and permeate through the membrane to the center of the fibers, while the other gases are rejected and expelled.

- Nitrogen Storage Tank - The generated nitrogen is stored in a nitrogen storage tank for later use.

- Nitrogen Distribution System - The stored nitrogen is then distributed to the end-user through a piping system and/or gas cylinder.

- Control Panel - A control panel is used to monitor and control the entire nitrogen generation system, including the compressor, pre-treatment unit, nitrogen membrane unit, and storage tank.

Nitrogen Generator Safety Considerations

Aside from standard safety concerns when operating a compressed air system, nitrogen generators have no additional safety concerns. However, since air is a mixture of primarily nitrogen and some oxygen, nitrogen systems cannot provide breathable air.

Some compressed air systems, properly specified, treated, and maintained, do provide breathing air. From that standpoint, nitrogen is potentially fatal if utilized to displace oxygen in an area where respiration is required, for example storage warehouses where nitrogen is used to preserve fresh fruit.

Sizing a Nitrogen Generation System

The 3 major questions we need to answer here are:

- What is your required rate of nitrogen consumption?

- What purity level does your process require?

- What nitrogen pressure is required?

A common question when switching from delivered to on-site nitrogen, is how to size the generator if you used to buy nitrogen by the gallon in liquid form, but the on-site gas generated is measured in CFM. There is a standard conversion method, that utilizes the ideal gas law, which equates the mass of liquid nitrogen to a volumetric gas.

This conversion requires consideration of pressure, purity, system losses, temperature, and other variables. If you’re interested in learning what your required nitrogen CFM is, contact us to have an expert help determine what you need.

Cost of A Nitrogen Generation System

An on-site nitrogen generation system not only provides the benefits listed above for production, but an added business benefit is how quickly the cost of a nitrogen system is recovered.

Nitrogen costs vary according to the supply method, but nitrogen can cost $2.50 - $5.00 CCF or more depending on where your facility is located and how far the nitrogen needs to be trucked in. An on-site nitrogen generator system can reduce this cost to $0.15 - $0.30 CCF. That’s a savings of 88% or more! In addition to the production savings, there are also financing options available making a nitrogen generator system easily accessible.

Here’s what a recent customer in the brewing industry had to say about the cost of their nitrogen generator system:

“Looking at the ROI we figured in almost less than a year it would pay for itself, which is pretty phenomenal. And even now, looking back at the data, we’ve seen a pretty substantial drop in our Co2 usage because we're using nitrogen for essentially all of our processes in the brewery.” – Khris Lloyd, Procurement Manager, Reuben’s Brews

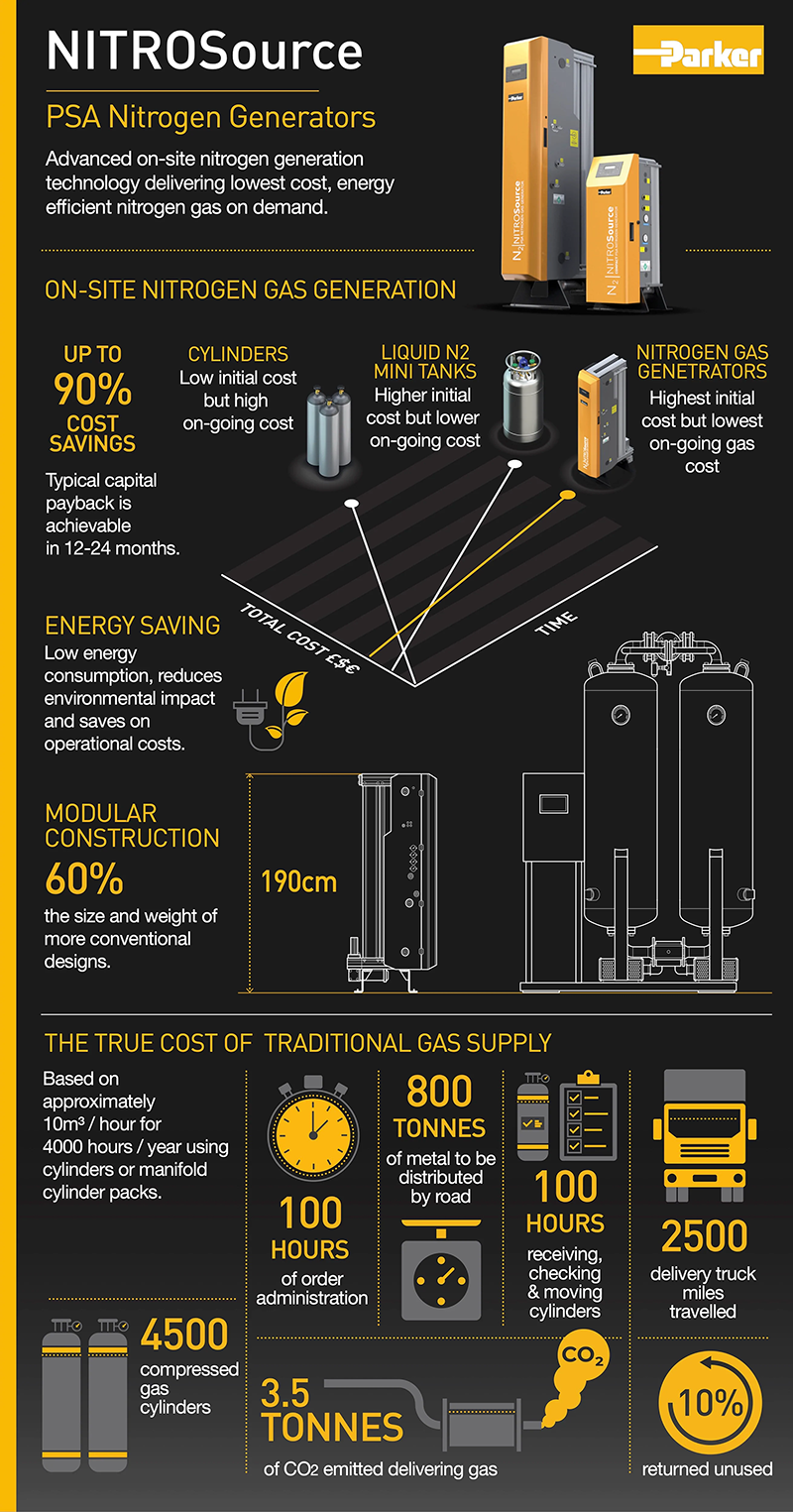

Check out this infographic from our premier line of Nitrogen generators, Parker NITROSource:

Switching From CO2 To An On-Site Nitrogen Generation System

This is the point in the article where you ask yourself, “Why are we still using CO2 for production processes and wasting time and money having gas brought in?” We were wondering the same thing…

With all the benefits to production efficiency, business expense and an easily recoupable investment, on-site nitrogen is a no-brainer for many facilities, especially beer producers. If you’d like to talk to our knowledgeable team about how a nitrogen generator system can help you, contact us here.

Learn more about Nitrogen Generators here.

Read the referenced customer case study or watch the video here.