Your Cart is Empty

How to Justify Capital Investment for Air Compressor and Vacuum Pump Systems

In this guide, you will learn how to justify the capital investment cost for a new Air Compressor & Vacuum Pump System. Measurable benefits, Request details, Who to involve and more.

You’ve found a way to solve a problem or make a big improvement in your process. It has the potential to save energy and time, reduce noise, or improve safety. You’ve even figured out the best solution, which happens to involve compressor and vacuum pump equipment. Now all that remains is the final hurdle – getting authorization for the capital expense to make it happen.

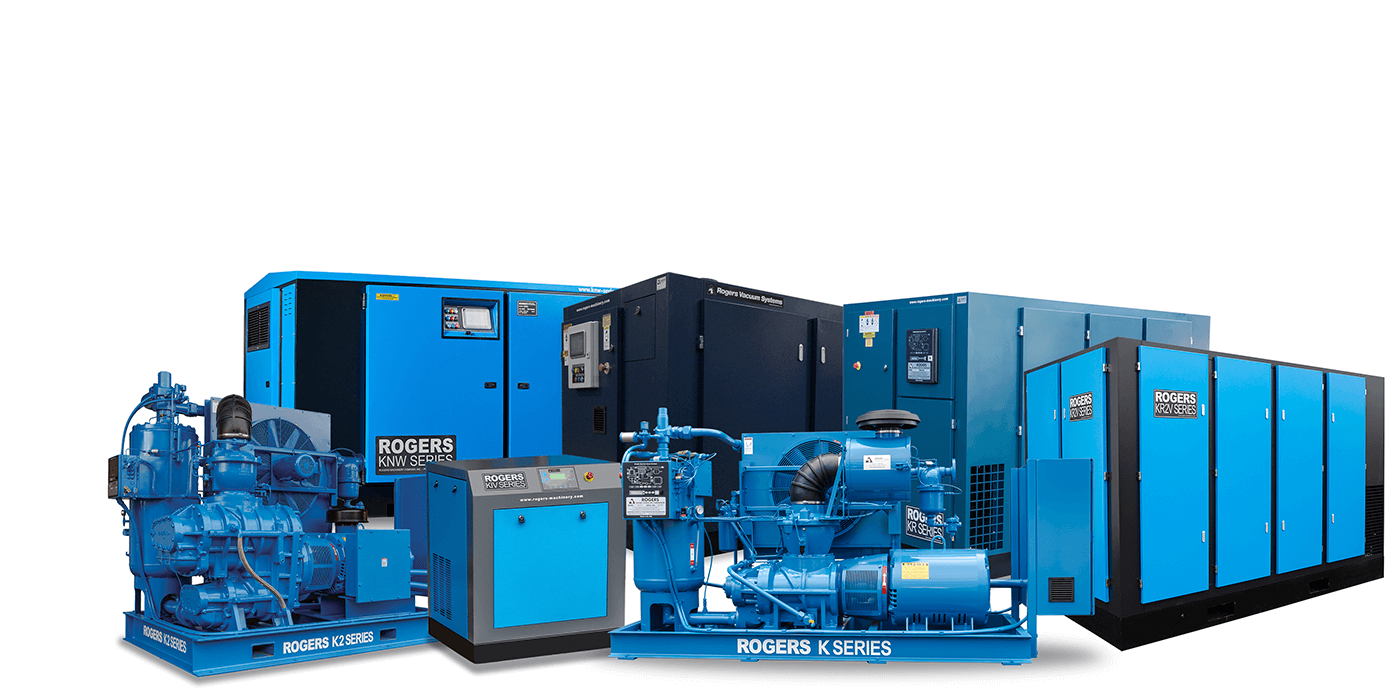

How to Justify the Investment for a New Rogers Compressed Air & Vacuum System

Businesses have a limited amount of capital available, so naturally any equipment investment will need to generate the most effective returns that align with company priorities. Whenever you need to justify a capital investment, it’s important to know the audience. That audience usually will include people in a variety of roles like purchasing agents, accountants, and management team members. Keep in mind the reason they need your proposal, and what’s most important to them and their decision-making process.

Depending on who will be reading the proposal and the company priorities, it may be important to highlight different benefits of a capital equipment project for compressed air and vacuum system improvements. Such benefits often come in one or more of the following forms:

- Cost Savings. Cost savings can come from fixed costs like facility overhead or variable costs (direct material expenses, direct labor expenses, and some factory overhead).

- Energy Savings. A vendor may be able to assist with energy analysis and savings projections, as well as energy incentive programs that can offset some costs.

- Production Gains. Improved process efficiency that leads to production gains is critical when the facility is pushing to increase production. At other times, when production is already at an optimal level, production gains may be less important.

- Decreased Maintenance. Reducing maintenance generally reduces maintenance costs as well as reducing maintenance hours.

- Improved Reliability & Reduced Downtime can often be achieved when replacing an older machine, or even when replacing a less efficient non-Rogers machine.

- Insurance. Sometimes insurance premiums may be lowered by updating equipment.

- Safety. The proposed equipment may enhance the safety of the process in some way, which would also result in fewer lost workdays.

- Other benefits may be related to legislation, health and safety, or the environment.

In addition, if your facility is currently renting equipment, purchasing the equipment using allocated capital budget may be seen as a way to free up expense budget for other purposes.

What Should a Capital Expenditure Request Include?

Your organization might have a template that is used in the capital expenditure process, or examples of previous requests. You can also start with the Rogers Machinery Compressed Air & Vacuum System Template.

In any case, most capital requisition proposals include information that’s necessary for the capital expense committee to make a decision. Most will include:

- Reason for the capital expense. This is the main “benefit” that answers the question “why” this expenditure is necessary, and what need it is addressing. As mentioned before, it may be to replace old or inefficient equipment, to save money through energy and maintenance savings, to comply with legislation or insurance requirements, or to improve environment, health, and safety.

- Base case, or a high-level technical description of the proposed solution.

- Alternatives to the base case, to show that other options have been considered to address the problem, although they may not be as desirable.

- Detailed cost analysis.The cost analysis quantifies the expected costs and benefits related to the project. This analysis should compare costs of any existing equipment (which may have heavy maintenance and energy costs) with anticipated costs of the proposed solution. It will also include payback, or how long it will take to pay for the equipment in profit.

- Company goals and objectives that are related to this project. Most companies have strategic and tactical goals, and the project likely ties in to one or more of those company priorities.

- Capital expenditures estimate. This estimate includes details of all expenditures necessary to implement the project.

- Benefits. Aside from the main reason for the expense, there are likely other side benefits that are anticipated.

- Lifecycle expectations. For equipment like compressed air and vacuum systems, it’s important to project the anticipated lifecycle over which the equipment can be depreciated.

Compressed Air & Vacuum System Request

Often the easiest way to get started on a capital expenditure request is to assemble the information that will be most useful for decision making. Rogers Machinery offers a template tailored for compressed air and vacuum systems that contains most of the information that is commonly used in these types of requests. Contact us to consult with one of our experts on your capital expense request.

What Is the Process for a Capital Expenditure Request?

Your company may have a formal procedure for capital expenditure requests that goes along with your analytical method, and related forms to fill out. Whether or not your company has a formalized process, any proposal generally passes through a series of major phases:

- Plan. Meet with your team to go over the solution and the information needed.

- Analysis. Gather technical details of the solution, cost figures, and details of projected benefits. When you have everything gathered and documented, ask someone to read it over and give you feedback to make sure you’re selling the benefits.

- Submit. When your request is completely documented, you’ll send it to the capital review team.

- Verification/clarification. Often the committee may come back with suggested revisions or with questions about the proposal. There may be questions that need clarification, like timeline for payback, or disposal of old equipment.

- Rejection or approval. The project may be approved for the final phase. If not, it may be set aside for consideration for a future budget.

- Purchasing. Purchasing is the last step before project implementation can begin.

Who Should Be Involved with a Capital Expenditure Request?

Wherever the idea originates for a necessary piece of equipment, there are generally several people working together to hammer out the proposal to make sure all the bases are covered. For various reasons, the team may require input from:

- Accountant to advise on the details of the capital request project and to help capture the initial investment, cash flow, cost of capital (discount rate), tax credits, operating expenses, and depreciation. They may be able to supply an example of a capex project that was approved, or a form for the company’s cost based decision model, if such a form exists.

- Engineer or project manager to document technical details of the project proposal.

- Team that might include the process engineer, maintenance manager, marketing analysts, and others to help assess the need and gather information.

- Vendor to assist with analysis, solution options, and cost projections. Rogers Machinery offers expertise to help define problems, develop solutions, and quantify variables like projected energy savings and efficiency. A vendor can also be well positioned to assist with known energy credits, grants, and savings programs that can make a capital expenditure an appealing and timely alternative.

When you have a project that will benefit the company and align with company goals, assembling all the information and making a case is the first step. Your project will be competing for a limited capital expenditure budget. Making your justification as clear and streamlined as possible allows the capital expense team to make the best decisions possible.

Rogers Machinery engineers can partner with you to gather information and analysis to support your capital expenditure justification for compressed air and vacuum systems and other process equipment. Contact us for assistance as you navigate the process.

Related Rogers Machinery Articles

Below is just a sampling of successful projects brought about with capital expenditure process assistance from Rogers Machinery.

- Vacuum Pump Technology Production Gains

- Hospital Consolidates Air Systems to Lower Costs and Improve Reliability

- Fujimi Goes Oil-Free And Saves With An Energy Incentive Payback Program

- Organic Valley was able to save approximately 32,000 kWHrs and 16,000 gallons of water usage per year.

- International Wire was able to get energy savings of over 400,000 kWh annually

The following Rogers Equipment article offers ideas about how to look at the value of new compressed air system:

Increase the Energy Efficiency of your Compressed Air System

Other Resources

EC&M “Do Your Homework When Trying to Justify Capital Expenditures”

CAGI’s Elements of Mechanical Equipment Life-Cycle Cost Analysis – Centrifugal Air Compressors