Your Cart is Empty

Nine Reasons To Consider On-Site Nitrogen Generation

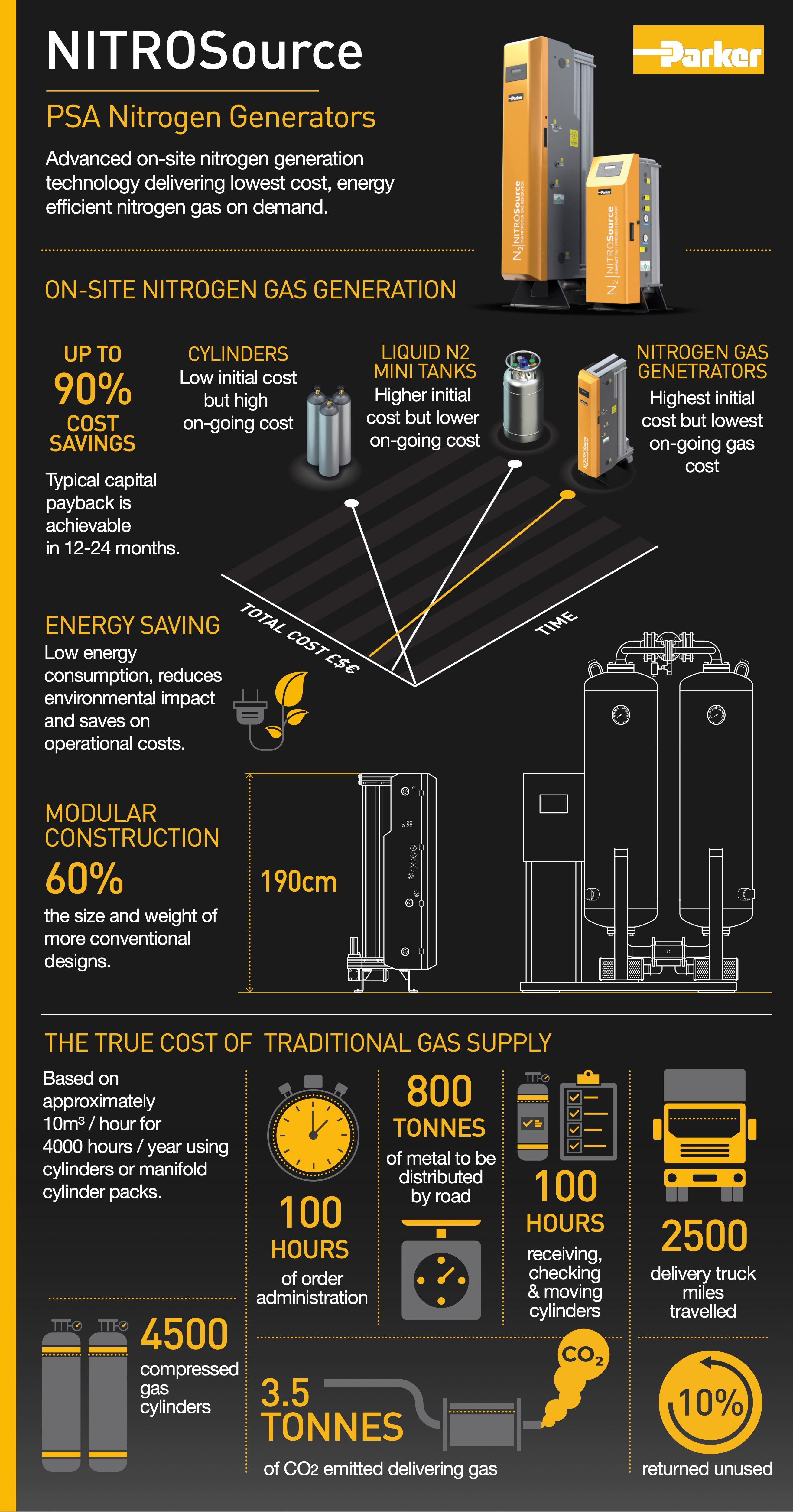

This article examines the three traditional gas supply methods and reasons why plant managers should consider using an on-site nitrogen generator as an alternative.

This article examines the three traditional gas supply methods and reasons why plant managers should consider using an on-site nitrogen generator as an alternative.

The majority of the world’s industrial nitrogen and oxygen is created through large scale cryogenic separation at an Air Separation Unit (ASU).

The product these ASUs manufacture is normally sold to end users as a liquid at nearly -200°C and stored in thermally insulated vessels or it is evaporated to a gas and compressed at pressures up to 300 bar g into steel cylinders.

One of the main problems, when confronted with a traditional gas supply, is that generally there is no indication on the vessel or cylinder as to how much product it contains and what flow rate is produced.

Another method of supplying industrial nitrogen is with an on-site nitrogen gas generator. A gas generator carries several benefits over traditional supplies including safety, convenience and cost savings.

Nitrogen Cylinders and Manifold Cylinder Packs (MCP)

Single nitrogen cylinders and manifold cylinder packs are supplied in a variety of volumes and fill pressures.

The stated cylinder content is not the actual usable gas volume. This depends on required delivery pressure and the need to guarantee the purity of gas.

Reason 1 - Rental Costs

Usually, three cylinders or MCPs are on site at any one time. One empty awaiting collection, one in use, and one full awaiting connection. All will be charged rental fees.

Reason 2 - Location

Cylinders have to be secured in purpose built racks for safety. MCPs have a large footprint and take up valuable floor space. Both need to be located in an area where a sudden release of gas cannot cause asphyxiation.

Reason 3 - Handling

Cylinders and MCPs are heavy and require special equipment to maneuver them into position — a time consuming and costly process. Downtime caused by changing cylinders can be considerable when calculated over the year.

Reason 4 - Waste due to pressure loss

To ensure gas quality above 34 bar g minimum remaining cylinder pressure, most industrial applications require a laboratory grade, built-in purifier cylinder equipped with internal consumable adsorbents, which adds considerable cost.

A standard 230 bar g cylinder carries the risk that the remaining 14% percent of the gas in the cylinder could be contaminated with water vapour and organic impurities (such as oils). These impurities are adsorbed into the surface of the cylinder walls and desorbed as the pressure reaches and drops below 34 bar g.

This contamination can build up over time and coat the pipework, regulators and application. The only way to prevent it is to stop using the cylinder supply when the pressure drops to 34 bar g. This equates to a 14 percent waste of money and gas for every cylinder or MCP.

Mini-bulk Storage of Liquid Nitrogen

Vacuum insulated liquid nitrogen vessels include an integral evaporator to convert the stored liquid to a usable gas. Mini tanks are supplied in various capacities and pressure options.

Reason 5 - Low flow rates

Because of the internal evaporator, flow rates are limited to relatively low levels given the stored capacity.

Reason 6 – Temperature duty cycle

Also due to the internal evaporator, extra time must be allowed for the temperature to achieve a sufficient level so as to ensure complete evaporation of the liquid.

Reason 7 – Static evaporation losses

It is not possible to have a 100 percent efficient heat insulated vessel because ambient heat transfer causes the liquid to heat up and evaporate. It is then vented to atmosphere (wasted), through a safety valve to prevent over pressurization on the vessel.

Some vessels have an economiser circuit that allows gas boil-off in the liquid vessel to be transferred to the gaseous phase of the evaporator. However, this is only useful when gas is being used by the application. When the economiser is not in use, the pressure builds and it is lost to atmosphere — wasting not only gas but the money that has been used to pay for it.

Bulk Liquid Nitrogen Vessels

Reason 8 – Bulk vessel heat leak

Cryogenic liquid storage vessels are designed to be as efficient as possible to minimize heating of the very cold liquid nitrogen at -196°C. However, some heat leak into the vessel is inevitable as no vacuum vessel is 100 percent efficient. The heat absorbed by the liquid will cause some of it to be vaporized into gas. This gas is called boil off. This boil-off is:

- Retained within the tank causing the pressure of the gas to rise

- Used by the customer through the economiser circuit

- If it is retained within the tank and the pressure rises above the safety limit, it will be vented to atmosphere and wasted

In reality, a certain amount of all three scenarios will occur. However, the more intermittent the demand for gas, the more potential there is for waste through boil off.

The table below details a typical monthly boil-off rates.

Reason 9 – Demand

A liquid tank used for standby, back-up or peak shaving is potentially very wasteful due to lack of demand or high boil-off rate. If a customer has too big a vessel for their application (for example if they originally had a high demand then this dropped but they kept the original vessel), there is a high potential for gas wastage.

If not used, a bulk vessel will lose all of its contents within approximately 3 months.

On-site Nitrogen Gas Generation

Nitrogen generators utilize proprietary selective permeation membrane and pressure swing adsorption (PSA) technologies to produce high purity nitrogen from compressed air. Nitrogen generators are designed to continually transform standard compressed air into nitrogen as safe, regulated pressures without operator attention. An on-site N2 generator will eliminate all of the above problems and increase profitability, reliability and sustainability.

A Parker NITROSource generator, for example, offers a unique design and advanced energy-saving technology that requires less compressed air to generate more nitrogen. Substantially lower servicing costs, reduced downtime, and longer working life make it the most cost-efficient nitrogen supply available. Additional benefits include:

A Parker NITROSource generator, for example, offers a unique design and advanced energy-saving technology that requires less compressed air to generate more nitrogen. Substantially lower servicing costs, reduced downtime, and longer working life make it the most cost-efficient nitrogen supply available. Additional benefits include:- Increased profitability – significantly lower unit gas cost, more up-time, NITROSource also incorporates energy-saving technology which matches demand to the application resulting in the user making further savings

- Increased reliability – gas available on demand 24/7, only pay for gas produced

- Sustainability – short payback on investment, long service life, low energy use and reduced CO2 footprint

With Parker’s vast industrial application knowledge gleaned over almost 30 years of designing and manufacturing gas generation systems, we are ideally suited to be able to help any customer to convert from delivered gas options to produce their own gas on demand.

For more details on how a NITROSource system can help with your gas needs please watch the video below.

Contact our experts to find out if a nitrogen generator will improve your compressed air system.

Learn more about Parker's Nitrosource generators.

This post was contributed by gas generation technology team member, Phil Green, industrial gas application manager, Parker Gas Separation and Filtration Division EMEA and first appeared on https://blog.parker.com

This post was contributed by gas generation technology team member, Phil Green, industrial gas application manager, Parker Gas Separation and Filtration Division EMEA and first appeared on https://blog.parker.com