Your Cart is Empty

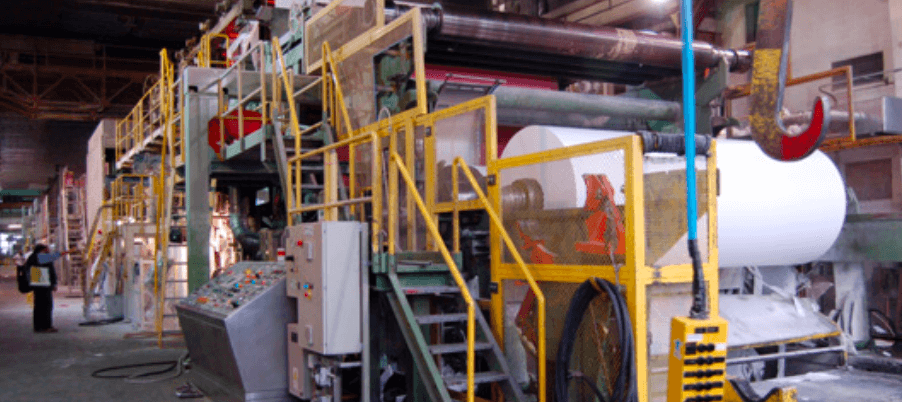

Starch Pumps for Pulp & Paper Processing

This article explains the requirements of starch pumps for Pulp and Paper Processing and recommends the Viking models that are well suited for those applications.

Starch is derived from corn, arrowroot, or potatoes. It is shear sensitive (thickens) and viscosity varies from a few centipoises to over 20,000 cP depending on the type of starch, concentration in the liquid, and temperature.

Viking pumps are used in the starch mixing and delivery systems (sometimes called kitchens) at paper mills and corrugators. Construction varies from cast iron to stainless steel, depending on the type of starch. Most starches are neutral or basic and are handled using cast iron. Starches that are more acidic may require stainless steel.

Raw starch may be abrasive if not completely dissolved or allowed to dry out. Cooked or hot starch (typically160°F) is not abrasive.

Common Starch Applications:

- Adhesives

- Sizing & finishing of textiles

- Foods

- Sizing paper

- Explosives

- Medicines

- Face powders

- Cosmetics

- Bookbinding

- Glucose

- Malt sugar

- Caramel

- Cattle feeds

Suggested Pulp and Paper Starch Pumps

4124B SERIES™ / 4124A SERIES™

- Cast Iron

- High viscosity sealing options (4124B Series™)

- Cartridge lipseal sealing options (4124A Series™)

- Capacities to 500 GPM

4624B SERIES™

- Cast Iron

- Sealing options available

- Hardened materials standard

- Capacities to 180 GPM

1124A SERIES™

- Cast Iron

- Abrasive resistant sealing option

- Low shear

- Capacities to 400 GPM

Download Starch Pumps Brochure