Your Cart is Empty

MD-Pneumatics - EX ATEX Blower Solutions

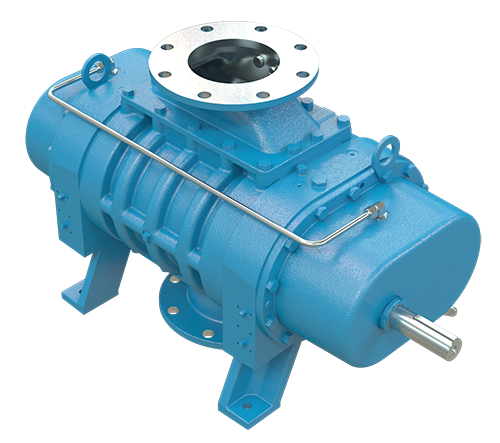

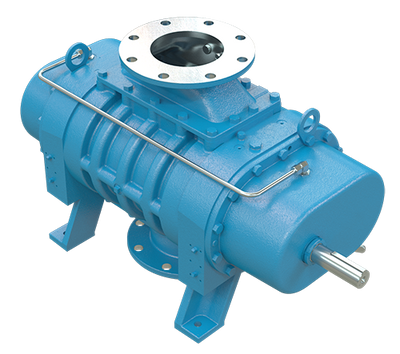

The MD-Kinney EX ATEX Series blowers are designed to deliver high-quality performance in hazardous areas. The MD-Kinney new EX ATEX Series meets the requirements for explosion protection regulation in Directive 2014/34/EU.

Specifications:

- Maximum Differential Pressure: 10 PSIG

- Max / Min RPM: 3600/11500

- Max Discharge Temp: 350° F

-

This product price is available on request only

Product details

M.D.-Kinney ATEX Series Industrial Blower Series

-

From Pneumatic Conveying to Process Gas boosting to Dairy Milking, M-D Pneumatics has a blower solution for your application. PD Plus blowers are a heavy-duty, high-pressure industrial blower and are renowned for their quality, dependability, and outstanding performance.

ATEX Blower features include:

- External classifications for Zones 1 or 2, Gas Groups IIA, IIB, and IIB+H2, and T3-T1 Temp Classes

- Internal classifications available including explosive gases for internal operating pressures less than 100 mbar

- Double envelope seals that are high pressure tested to provide the highest safety level possible

- Nominal displacement range of 212 to 3823 m3/hr cooling coils to promote longer oil, bearing, and seal life

- Stainless steel cross-over tubing between oil sumps for harsh environments

- Multiple instrumentation ports for monitoring temperatures, vibrations, fluids, pressure, and vacuum

- Hydrostatic integrity tests performed on assembled housing, endplates, and ports

- M-D Pneumatics MD Plus lubrication designed specifically for the performance demanded

- Standard shaft or c-flange versions available to meet installation requirements

- Materials of construction options include cast iron, ductile iron, and stainless steel

Applications:

- Pneumatic conveying

- Silo loading and unloading

- Process gas boosting

- Elevated pressure applications

-

MODEL Gear Size (in.) Max Differential Pressure**

(PSIG)

Maximum Vacuum (in-Hg) Max / Min

RPMMax

Allowed

Working

Pressure(PSIG)

Max

Discharge

Temp (F°)EX3204 3.25 10 15 3600 /1150 34 350 F° EX3206 3.25 10 15 34 EX3210 3.25 10 15 34 EX4009 4 15 15 34 EX4012 4 15 15 34 EX5507 5.5 10 15 34 EX5511 5.5 10 15 34 EX5514 5.5 10 15 34 EX5518 5.5 10 15 34 -

M.D. Kinney Vacuum Pumps & Boosters Line Card

M-D Pneumatics EX ATEX Solutions Cut Sheet - EX3200 ATEX Series Blowers

M-D Pneumatics EX ATEX Solutions Cut Sheet - EX4000 ATEX Series Blowers

-

Features:

Mechanical Seals, Integral Pressure Lubrication

This series incorporates mechanical seals on the rotor shafts and the drive shaft, flanged port fittings, water-cooled drive shaft seal, integral pressure lubrication system with water-cooled heat exchanger, and cooling coils in the end covers. Water-cooled drive shaft seal not included with optional motor mounting flange versions.

Slinger Seals, Integral Pressure Lubrication

This series utilizes a mechanical drive shaft seal in conjunction with a non-contacting, non-wearing slinger seal on the rotor shafts, flanged port fittings, water-cooled drive shaft seal, and integral pressure lubrication system with a water-cooled heat exchanger. Cooling coils are not included.

Mechanical Seals

This series incorporates mechanical sealing on the rotor shafts and the drive shaft, flanged port fittings, water-cooled drive shaft seal, and cooling coils in the end covers.

Slinger Seals

These series utilize a mechanical drive shaft seal in conjunction with a non-contacting, non-wearing slinger seal on the rotor shafts, water-cooled drive shaft seal, flanged port fittings, and are dependable performers for air and many gas applications. Cooling coils are not included. -

MD-Kinney EX ATEX Solutions Positive Displacement Blowers & Vacuum Boosters Brochure

- Description

From Pneumatic Conveying to Process Gas boosting to Dairy Milking, M-D Pneumatics has a blower solution for your application. PD Plus blowers are a heavy-duty, high-pressure industrial blower and are renowned for their quality, dependability, and outstanding performance.

ATEX Blower features include:

- External classifications for Zones 1 or 2, Gas Groups IIA, IIB, and IIB+H2, and T3-T1 Temp Classes

- Internal classifications available including explosive gases for internal operating pressures less than 100 mbar

- Double envelope seals that are high pressure tested to provide the highest safety level possible

- Nominal displacement range of 212 to 3823 m3/hr cooling coils to promote longer oil, bearing, and seal life

- Stainless steel cross-over tubing between oil sumps for harsh environments

- Multiple instrumentation ports for monitoring temperatures, vibrations, fluids, pressure, and vacuum

- Hydrostatic integrity tests performed on assembled housing, endplates, and ports

- M-D Pneumatics MD Plus lubrication designed specifically for the performance demanded

- Standard shaft or c-flange versions available to meet installation requirements

- Materials of construction options include cast iron, ductile iron, and stainless steel

Applications:

- Pneumatic conveying

- Silo loading and unloading

- Process gas boosting

- Elevated pressure applications

- Specifications

MODEL Gear Size (in.) Max Differential Pressure**

(PSIG)

Maximum Vacuum (in-Hg) Max / Min

RPMMax

Allowed

Working

Pressure(PSIG)

Max

Discharge

Temp (F°)EX3204 3.25 10 15 3600 /1150 34 350 F° EX3206 3.25 10 15 34 EX3210 3.25 10 15 34 EX4009 4 15 15 34 EX4012 4 15 15 34 EX5507 5.5 10 15 34 EX5511 5.5 10 15 34 EX5514 5.5 10 15 34 EX5518 5.5 10 15 34 - Resources

M.D. Kinney Vacuum Pumps & Boosters Line Card

M-D Pneumatics EX ATEX Solutions Cut Sheet - EX3200 ATEX Series Blowers

M-D Pneumatics EX ATEX Solutions Cut Sheet - EX4000 ATEX Series Blowers

- Components

Features:

Mechanical Seals, Integral Pressure Lubrication

This series incorporates mechanical seals on the rotor shafts and the drive shaft, flanged port fittings, water-cooled drive shaft seal, integral pressure lubrication system with water-cooled heat exchanger, and cooling coils in the end covers. Water-cooled drive shaft seal not included with optional motor mounting flange versions.

Slinger Seals, Integral Pressure Lubrication

This series utilizes a mechanical drive shaft seal in conjunction with a non-contacting, non-wearing slinger seal on the rotor shafts, flanged port fittings, water-cooled drive shaft seal, and integral pressure lubrication system with a water-cooled heat exchanger. Cooling coils are not included.

Mechanical Seals

This series incorporates mechanical sealing on the rotor shafts and the drive shaft, flanged port fittings, water-cooled drive shaft seal, and cooling coils in the end covers.

Slinger Seals

These series utilize a mechanical drive shaft seal in conjunction with a non-contacting, non-wearing slinger seal on the rotor shafts, water-cooled drive shaft seal, flanged port fittings, and are dependable performers for air and many gas applications. Cooling coils are not included.- Brochures

MD-Kinney EX ATEX Solutions Positive Displacement Blowers & Vacuum Boosters Brochure

Rent product

Interested in renting MD-Pneumatics - EX ATEX Blower Solutions? Please fill in the form below and we will get back to you in the shortest time.

{formbuilder:10226}