Your Cart is Empty

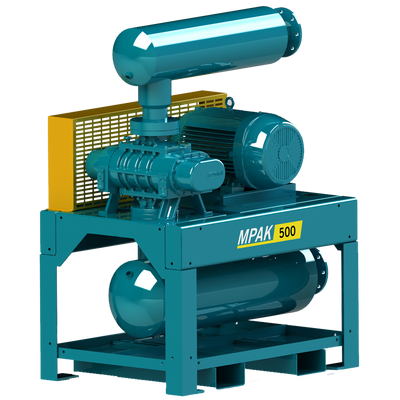

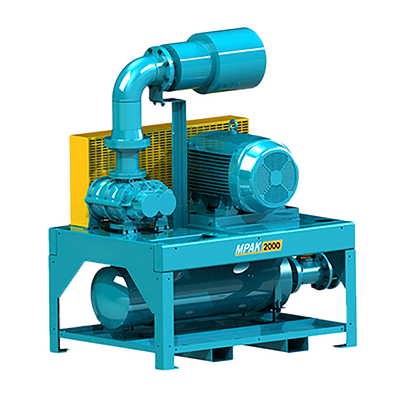

MD-Pneumatics - MPAK Blower Packages

The MD-Pneumatics Compact Rotary Blower Packages are dependable open-pressure packages that provide economical high-volume air sources for a variety of different applications and vital industries.

Flow: 250-1985 CFM

Pressure: 5-15 psi

Vacuum: 12-17 in. Hg

-

This product price is available on request only

Product details

M.D. Pneumatic- MPAK Blower Packages

-

From Pneumatic Conveying to Process Gas boosting to Dairy Milking, M-D Pneumatics has a blower solution for your application. PD Plus blowers are a heavy-duty, high-pressure industrial blower and are renowned for their quality, dependability, and outstanding performance.

MpAK Series blower packages offer many distinct advantages and features including:

- Engineered with options. Get maximum performance, extreme reliability and cost efficiencies by sizing M-D Pneumatics air blowers to your application: CP Series, PD Plus, or Qx.

- Cost effective. Each MPAK is accurately sized to your application specifications. The most flexible, hassle-free design.

- Maintenance friendly design. Both open and enclosed packages allow easy access to components. Enclosed design features clear-view window to keep a close check on blower oil levels.

- Easy to operate. Standard gauges measure pressure, temperature, and filter life.

- Ready to go. MPAK packages are factory assembled and require minimal training at start up.

- Easy to move. Mounting base includes integral fork truck pockets for easy transportation and positioning.

- Retrofittable. Field retrofittable enclosure option available.

Additional Features

- TEFC motor standard with 1.15 service factor

- Welded steel motor slide base

- Matched V-belt drive with 1.1 service factor

- OSHA belt guard with flow-through ventilation keeps belts running cool

- Low pressure drop inlet filter or silencer

- Suitable for indoor or outdoor installation

- Shipped completely assembled for convenient installation*

- Enclosure is field mountable

- Height consideration may require partial disassembly for shipment

VBXpert Portal sizing software should be used to accurately select the MPAK components for each application. Contact your local sales representative for assistance.

Applications:

- Pneumatic Conveying

- Water Aeration

-

Model Lower CFM Lower m3/H Upper CFM at min. pressure Upper m3/H at min. pressure Max pressure PSIG Max pressure barg inHg/mbar MPAK 500 (All units have 4" inlet and discharge flanges) CP4005-A6L2CV1-A 250 425 375 638 10 0.69 12 inHg | 406.37 mbar CP4007-A6L2CV1-A 495 842 15* 1.03 12 inHg | 406.37 mbar CP5006-A6L2CV1-A 530 901 15* 1.03 12 inHg | 575.69 mbar PD+4009-A3L2CV2-A 418 711 15 1.03 17 inHg | 575.69 mbar PD+4012-A3L2CV2-A 570 969 15 1.03 17 inHg | 575.69 mbar QX3208-A4L3CV2-A 440 714 15* 1.03 17 inHg | 575.69 mbar MPAK 1000 (All units have 6" inlet and discharge flanges) CP 5009-A6L2CV1-A 500 850 800 1360 14 0.97 12 inHg | 406.37 mbar CP 6008-A6L2CV1-A 805 1369 15* 1.03 12 inHg | 406.37 mbar PD+5507-A3L2CV2-A 708 1204 15 1.03 17 inHg | 575.69 mbar PD+5511-ACL2CV2-A 955 1624 15 1.03 17 inHg | 575.69 mbar QX 4610-A4L3CV2-A 888 1510 15* 1.03 17 inHg | 575.69 mbar QX 6009-A4L3CV2-A 975 1658 15* 1.03 17 inHg | 575.69 mbar MPAK 2000 (All units have 8" inlet and 6" discharge flanges) CP6015-A6L2CV2-A 1000 1700 1505 2559 7 0.48 12 inHg | 406.37 mbar CP7011-A6L2CV2-A 1350 2295 10 0.69 12 inHg | 406.37 mbar CP7018-A6L2CV2-A 1800 3060 6 0.41 12 inHg | 406.37 mbar PD7010-A3L2CV2-A 1565 2661 15* 1.03 17 inHg | 575.69 mbar PD7013-A3L2CV2-A 1985 3375 15* 1.03 17 inHg | 575.69 mbar QX6015-A4L3CV2-A 1720 2924 15* 1.03 17 inHg | 575.69 mbar *MPAK limited to 15 psig to stay under ASME code requirements.

-

M-D Pneumatics Vacuum Pumps & Boosters Line Card

M-D Pneumatics MPAK Blower Package Cut Sheet

-

Features:

Mechanical Seals, Integral Pressure Lubrication

This series incorporates mechanical seals on the rotor shafts and the drive shaft, flanged port fittings, water-cooled drive shaft seal, integral pressure lubrication system with water-cooled heat exchanger, and cooling coils in the end covers. Water-cooled drive shaft seal not included with optional motor mounting flange versions.

Slinger Seals, Integral Pressure Lubrication

This series utilizes a mechanical drive shaft seal in conjunction with a non-contacting, non-wearing slinger seal on the rotor shafts, flanged port fittings, water-cooled drive shaft seal, and integral pressure lubrication system with a water-cooled heat exchanger. Cooling coils are not included.

Mechanical Seals

This series incorporates mechanical sealing on the rotor shafts and the drive shaft, flanged port fittings, water-cooled drive shaft seal, and cooling coils in the end covers.

Slinger Seals

These series utilize a mechanical drive shaft seal in conjunction with a non-contacting, non-wearing slinger seal on the rotor shafts, water-cooled drive shaft seal, flanged port fittings, and are dependable performers for air and many gas applications. Cooling coils are not included. -

MD-Kinney Vacuum Pumps & Boosters Product Brochure

MD-Kinney Rotary Positive Displacement Blowers Brochure-English

MD-Kinney Rotary Positive Displacement Blowers Brochure-Spanish

- Description

From Pneumatic Conveying to Process Gas boosting to Dairy Milking, M-D Pneumatics has a blower solution for your application. PD Plus blowers are a heavy-duty, high-pressure industrial blower and are renowned for their quality, dependability, and outstanding performance.

MpAK Series blower packages offer many distinct advantages and features including:

- Engineered with options. Get maximum performance, extreme reliability and cost efficiencies by sizing M-D Pneumatics air blowers to your application: CP Series, PD Plus, or Qx.

- Cost effective. Each MPAK is accurately sized to your application specifications. The most flexible, hassle-free design.

- Maintenance friendly design. Both open and enclosed packages allow easy access to components. Enclosed design features clear-view window to keep a close check on blower oil levels.

- Easy to operate. Standard gauges measure pressure, temperature, and filter life.

- Ready to go. MPAK packages are factory assembled and require minimal training at start up.

- Easy to move. Mounting base includes integral fork truck pockets for easy transportation and positioning.

- Retrofittable. Field retrofittable enclosure option available.

Additional Features

- TEFC motor standard with 1.15 service factor

- Welded steel motor slide base

- Matched V-belt drive with 1.1 service factor

- OSHA belt guard with flow-through ventilation keeps belts running cool

- Low pressure drop inlet filter or silencer

- Suitable for indoor or outdoor installation

- Shipped completely assembled for convenient installation*

- Enclosure is field mountable

- Height consideration may require partial disassembly for shipment

VBXpert Portal sizing software should be used to accurately select the MPAK components for each application. Contact your local sales representative for assistance.

Applications:

- Pneumatic Conveying

- Water Aeration

- Specifications

Model Lower CFM Lower m3/H Upper CFM at min. pressure Upper m3/H at min. pressure Max pressure PSIG Max pressure barg inHg/mbar MPAK 500 (All units have 4" inlet and discharge flanges) CP4005-A6L2CV1-A 250 425 375 638 10 0.69 12 inHg | 406.37 mbar CP4007-A6L2CV1-A 495 842 15* 1.03 12 inHg | 406.37 mbar CP5006-A6L2CV1-A 530 901 15* 1.03 12 inHg | 575.69 mbar PD+4009-A3L2CV2-A 418 711 15 1.03 17 inHg | 575.69 mbar PD+4012-A3L2CV2-A 570 969 15 1.03 17 inHg | 575.69 mbar QX3208-A4L3CV2-A 440 714 15* 1.03 17 inHg | 575.69 mbar MPAK 1000 (All units have 6" inlet and discharge flanges) CP 5009-A6L2CV1-A 500 850 800 1360 14 0.97 12 inHg | 406.37 mbar CP 6008-A6L2CV1-A 805 1369 15* 1.03 12 inHg | 406.37 mbar PD+5507-A3L2CV2-A 708 1204 15 1.03 17 inHg | 575.69 mbar PD+5511-ACL2CV2-A 955 1624 15 1.03 17 inHg | 575.69 mbar QX 4610-A4L3CV2-A 888 1510 15* 1.03 17 inHg | 575.69 mbar QX 6009-A4L3CV2-A 975 1658 15* 1.03 17 inHg | 575.69 mbar MPAK 2000 (All units have 8" inlet and 6" discharge flanges) CP6015-A6L2CV2-A 1000 1700 1505 2559 7 0.48 12 inHg | 406.37 mbar CP7011-A6L2CV2-A 1350 2295 10 0.69 12 inHg | 406.37 mbar CP7018-A6L2CV2-A 1800 3060 6 0.41 12 inHg | 406.37 mbar PD7010-A3L2CV2-A 1565 2661 15* 1.03 17 inHg | 575.69 mbar PD7013-A3L2CV2-A 1985 3375 15* 1.03 17 inHg | 575.69 mbar QX6015-A4L3CV2-A 1720 2924 15* 1.03 17 inHg | 575.69 mbar *MPAK limited to 15 psig to stay under ASME code requirements.

- Resources

M-D Pneumatics Vacuum Pumps & Boosters Line Card

M-D Pneumatics MPAK Blower Package Cut Sheet

- Components

Features:

Mechanical Seals, Integral Pressure Lubrication

This series incorporates mechanical seals on the rotor shafts and the drive shaft, flanged port fittings, water-cooled drive shaft seal, integral pressure lubrication system with water-cooled heat exchanger, and cooling coils in the end covers. Water-cooled drive shaft seal not included with optional motor mounting flange versions.

Slinger Seals, Integral Pressure Lubrication

This series utilizes a mechanical drive shaft seal in conjunction with a non-contacting, non-wearing slinger seal on the rotor shafts, flanged port fittings, water-cooled drive shaft seal, and integral pressure lubrication system with a water-cooled heat exchanger. Cooling coils are not included.

Mechanical Seals

This series incorporates mechanical sealing on the rotor shafts and the drive shaft, flanged port fittings, water-cooled drive shaft seal, and cooling coils in the end covers.

Slinger Seals

These series utilize a mechanical drive shaft seal in conjunction with a non-contacting, non-wearing slinger seal on the rotor shafts, water-cooled drive shaft seal, flanged port fittings, and are dependable performers for air and many gas applications. Cooling coils are not included.- Brochures

MD-Kinney Vacuum Pumps & Boosters Product Brochure

MD-Kinney Rotary Positive Displacement Blowers Brochure-English

MD-Kinney Rotary Positive Displacement Blowers Brochure-Spanish

Rent product

Interested in renting MD-Pneumatics - MPAK Blower Packages? Please fill in the form below and we will get back to you in the shortest time.

{formbuilder:10226}