Your Cart is Empty

Pneumatic Products - PHD Series Compressed Air Dryer

Compressed air drying applications that simply want seasonal protection against freezing are exactly what the standard PHD Series desiccant dryers are designed to address.

- Flow: 300 - 3,200 SCFM

- Pressure: 60 - 150 PSIG

-

This product price is available on request only

Product details

The PHD Series is engineered to deliver ISO 8573.1 Air Quality and reduce purge air consumption.

-

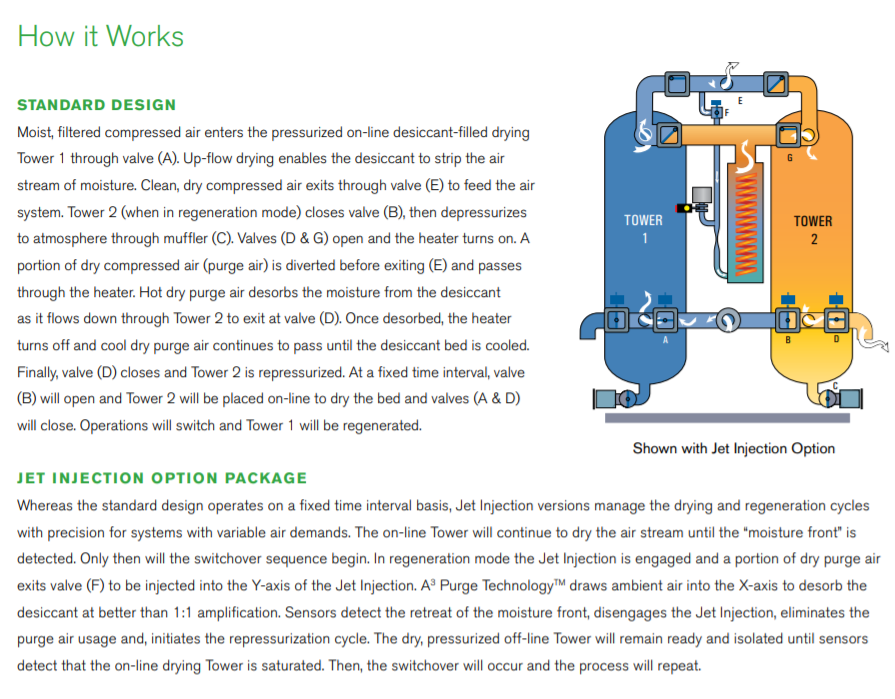

Overview Compressed air drying applications that simply want seasonal protection against freezing are exactly what the standard PHD Series desiccant dryers are designed to address. Standard models automatically provide ISO 8573.1 Class 2 (-40°C/-40°F) dew points to protect usage points from freezing during the winter months and, Class 3 (-20°C/ -4°F) dew points to keep air systems nice and dry all summer long. Features - Optional Jet Injection Energy Management System guarantees -40°C/-40°F pressure dew points all year long and, fast returns-on-investment.

- A³ Purge TechnologyT injects energy savings of 9% to 15% result in direct relation to plant air demands.

-

Model Inlet Flow1 @ 100 psig 100oF Heather Rated Output (kW) Average (kW) Dimensions (inches) Inlet/Outlet Connections (In) Approx Weight (lbs) Filtration2 H W D PHD-300 300 5 2.7 98 48 47 1.5" NPT 1400 PCS13401 PHD-400 400 7 3.6 104 53 55 1.5" NPT 1800 PCS15001 PHD-500 500 7 4.5 105 53 56 1.5" NPT 1800 PCS15001 PHD-600 600 8 5.4 108 55 57 2" NPT 2000 PCS16001 PHD-750 750 10 6.8 114 60 65 2" NPT 2400 PCS18001 PHD-900 900 12 8.2 114 60 65 3" FLG 2400 OCS19501 PHD-1050 1050 14 9.5 113 64 66 3" FLG 2900 PCS112001 PHD-1300 1300 17 11.8 118 66 77 3" FLG 3400 PCC11403 PHD-1500 1500 19 18.6 119 80 83 4" FLG 5100 PCC118003 PHD-1800 1800 23 16.3 119 80 82 4" FLG 5100 PCC118003 PHD-2200 2200 28 20.0 127 85 87 4" FLG 7800 PCC124004 PHD-2600 2600 33 23.6 127 85 87 6" FLG 7800 PCC136003 PHD-3200 3200 40 29.1 125 97 91 6" FLG 9000 PCC136003 1 Performance data per CAGI Standard ADF 200 for Dual-Stage Regenerative Desiccant Compressed Air Dryer. Rating conditions are 100°F (37.8°C) inlet 100 psig (6.9 bar)

inlet pressure, 100% relative humidity, 100°F (37.8°C) ambient temperature, and 5 psi (0.35 bar) pressure drop. * Consult factory for larger models.

2 Prefilter element type SU: Afterfilter element type HT.

- Description

Overview Compressed air drying applications that simply want seasonal protection against freezing are exactly what the standard PHD Series desiccant dryers are designed to address. Standard models automatically provide ISO 8573.1 Class 2 (-40°C/-40°F) dew points to protect usage points from freezing during the winter months and, Class 3 (-20°C/ -4°F) dew points to keep air systems nice and dry all summer long. Features - Optional Jet Injection Energy Management System guarantees -40°C/-40°F pressure dew points all year long and, fast returns-on-investment.

- A³ Purge TechnologyT injects energy savings of 9% to 15% result in direct relation to plant air demands.

- Specifications

Model Inlet Flow1 @ 100 psig 100oF Heather Rated Output (kW) Average (kW) Dimensions (inches) Inlet/Outlet Connections (In) Approx Weight (lbs) Filtration2 H W D PHD-300 300 5 2.7 98 48 47 1.5" NPT 1400 PCS13401 PHD-400 400 7 3.6 104 53 55 1.5" NPT 1800 PCS15001 PHD-500 500 7 4.5 105 53 56 1.5" NPT 1800 PCS15001 PHD-600 600 8 5.4 108 55 57 2" NPT 2000 PCS16001 PHD-750 750 10 6.8 114 60 65 2" NPT 2400 PCS18001 PHD-900 900 12 8.2 114 60 65 3" FLG 2400 OCS19501 PHD-1050 1050 14 9.5 113 64 66 3" FLG 2900 PCS112001 PHD-1300 1300 17 11.8 118 66 77 3" FLG 3400 PCC11403 PHD-1500 1500 19 18.6 119 80 83 4" FLG 5100 PCC118003 PHD-1800 1800 23 16.3 119 80 82 4" FLG 5100 PCC118003 PHD-2200 2200 28 20.0 127 85 87 4" FLG 7800 PCC124004 PHD-2600 2600 33 23.6 127 85 87 6" FLG 7800 PCC136003 PHD-3200 3200 40 29.1 125 97 91 6" FLG 9000 PCC136003 1 Performance data per CAGI Standard ADF 200 for Dual-Stage Regenerative Desiccant Compressed Air Dryer. Rating conditions are 100°F (37.8°C) inlet 100 psig (6.9 bar)

inlet pressure, 100% relative humidity, 100°F (37.8°C) ambient temperature, and 5 psi (0.35 bar) pressure drop. * Consult factory for larger models.

2 Prefilter element type SU: Afterfilter element type HT.- Brochures

Rent product

Interested in renting Pneumatic Products - PHD Series Compressed Air Dryer? Please fill in the form below and we will get back to you in the shortest time.

{formbuilder:10226}