Your Cart is Empty

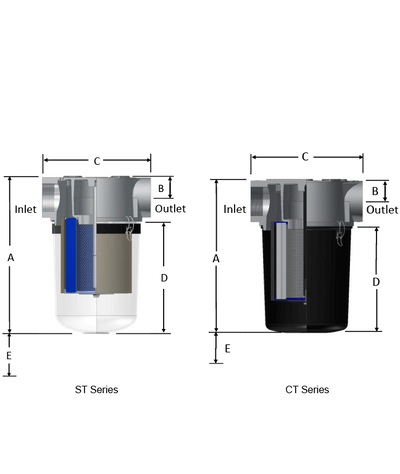

Solberg - ST Series Vacuum Filters

Inline Straight-Through Vacuum Filters

The centrifugal force from intake air causes particulate to separate

from the air stream, forcing it to the outer cover perimeter and

out through the discharge port. The SpinMeister™ Precleaner

eliminates large objects from entering the air stream. The air stream

then enters the particulate filter (optional) and is filtered by a

99+% efficient pleated element.

-

This product price is available on request only

Product details

-

Features - Easy maintenance due to see through bucket

- Compact design for space restrictions; min. service area

- Inlet above element for extended element life &

maintenance intervals - Corrosive resistant cast aluminum top with machined

connections and integrated baffle design - Shatter-resistant polycarbonate drop down bucket

Options - Vacuum gauge

- Taps for gauge and mounting brackets

- Swing bolts for heavy duty environments

- Drain ports

- Various media

- Reverse pulse configuration

- Spool piece extender

Applications - Ash Handling

- Cement

- Compressor-Piston

- Envelope Manufacturing

- Factory Automation

- Glass, Ceramic-Vacuum

- Paper Processing

- Pneumatic Conveying Systems

- Vacuum Packaging

- Vacuum Systems-Central

- Waste Water Aeration

- Woodworking

- Intake Suction Filters

- Remote Installations for Piston and Screw Compressors

-

Technical Specifications - Vacuum Rating: medium vacuum service*

- Temp (continuous): min ‐15°F (‐26°C) max 220°F (104°C)

- Filter change out differential: 15-20" H2O (37‐50 mbar) over initial Δ P

- Polyester: 99%+ removal efficiency standard to 5 micron

- Paper: 99%+ removal efficiency standard to 2 micron

-

ST Series Inline Straight-Through Vacuum Filter Datasheet Inlet Vacuum Filters Maintenance Manual

- Description

Features - Easy maintenance due to see through bucket

- Compact design for space restrictions; min. service area

- Inlet above element for extended element life &

maintenance intervals - Corrosive resistant cast aluminum top with machined

connections and integrated baffle design - Shatter-resistant polycarbonate drop down bucket

Options - Vacuum gauge

- Taps for gauge and mounting brackets

- Swing bolts for heavy duty environments

- Drain ports

- Various media

- Reverse pulse configuration

- Spool piece extender

Applications - Ash Handling

- Cement

- Compressor-Piston

- Envelope Manufacturing

- Factory Automation

- Glass, Ceramic-Vacuum

- Paper Processing

- Pneumatic Conveying Systems

- Vacuum Packaging

- Vacuum Systems-Central

- Waste Water Aeration

- Woodworking

- Intake Suction Filters

- Remote Installations for Piston and Screw Compressors

- Specifications

Technical Specifications - Vacuum Rating: medium vacuum service*

- Temp (continuous): min ‐15°F (‐26°C) max 220°F (104°C)

- Filter change out differential: 15-20" H2O (37‐50 mbar) over initial Δ P

- Polyester: 99%+ removal efficiency standard to 5 micron

- Paper: 99%+ removal efficiency standard to 2 micron

- Resources

ST Series Inline Straight-Through Vacuum Filter Datasheet Inlet Vacuum Filters Maintenance Manual - Brochures

- Videos

Rent product

Interested in renting Solberg - ST Series Vacuum Filters? Please fill in the form below and we will get back to you in the shortest time.

{formbuilder:10226}