Your Cart is Empty

Solberg - WL Series Vacuum Filters

Medium/High Vacuum

Solberg’s WL Series Vacuum Filters are designed for a variety of industrial and semicon processes where rapid thermal and/or pressure cycles create harsh operating conditions. Ideal for medium-high vacuum applications that utilize vacuum furnaces or deposition tools, the WL series comes standard with a variety of vacuum-rated flange options and replaceable filter elements that offer superior protection and longevity for the vacuum system. Housings in this series are 100% helium leak tested to ensure vacuum integrity and verify leak rates down to 1x 10-5 mbar/l/s.

View Solberg products, parts, and services.

-

This product price is available on request only

Product details

-

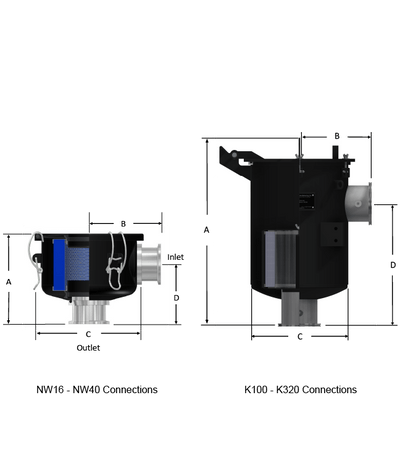

Features NW16 - NW40 Flange Connections:

- ISO flange connections

- Stainless steel ISO flange

- Buna o-ring sealed

- Seamless drawn housings

- Corrosive resistant carbon steel construction

- Powder coat finish (black models)

- O-ring housing seal

- Stainless steel torsion clips

K100 - K320 Connections:

- ISO-K stainless steel flanges standard

- Machined flange surface to RMS63, uncoated

- High quality vacuum service components

- Corrosive resistant black powder coat carbon steel

- KF10 differential ports for accurate vacuum ΔP readings

- Machined & polished sealing surfaces on ISO flange faces for reliable vacuum performance on all flange types

- K200 housings and larger have domed lid to minimize deflection and increase durability

Options NW16 - NW40 Flange Connections:

- Contact factory for larger sizes & ISO flanges

- Viton seals

- Stainless steel (select models)

- Activated alumina, activated zeolite media available for foreline trap and other applications

K100 - K320 Connections:

- Filter media options available to meet strict process requirements: PTFE, PTFE Glass, SS mesh, and more

- If required, tanks can be tested to a lower leak rate

- ISO flange connections

-

Technical Specifications - Rated vacuum leak rate of 1x10-5 mbar/l/sec or better (verified by helium leak test)

- Temp (continuous): min -15°F (-26°C) max 220°F (104°C)

- Filter change out differential: 28 – 37 Torr over initial ΔP

- Polyester: 99%+ efficiency to 5 micron

-

WL Series Vacuum Filter Datasheet Inlet Vacuum Filters Maintenance Manual

- Description

Features NW16 - NW40 Flange Connections:

- ISO flange connections

- Stainless steel ISO flange

- Buna o-ring sealed

- Seamless drawn housings

- Corrosive resistant carbon steel construction

- Powder coat finish (black models)

- O-ring housing seal

- Stainless steel torsion clips

K100 - K320 Connections:

- ISO-K stainless steel flanges standard

- Machined flange surface to RMS63, uncoated

- High quality vacuum service components

- Corrosive resistant black powder coat carbon steel

- KF10 differential ports for accurate vacuum ΔP readings

- Machined & polished sealing surfaces on ISO flange faces for reliable vacuum performance on all flange types

- K200 housings and larger have domed lid to minimize deflection and increase durability

Options NW16 - NW40 Flange Connections:

- Contact factory for larger sizes & ISO flanges

- Viton seals

- Stainless steel (select models)

- Activated alumina, activated zeolite media available for foreline trap and other applications

K100 - K320 Connections:

- Filter media options available to meet strict process requirements: PTFE, PTFE Glass, SS mesh, and more

- If required, tanks can be tested to a lower leak rate

- ISO flange connections

- Specifications

Technical Specifications - Rated vacuum leak rate of 1x10-5 mbar/l/sec or better (verified by helium leak test)

- Temp (continuous): min -15°F (-26°C) max 220°F (104°C)

- Filter change out differential: 28 – 37 Torr over initial ΔP

- Polyester: 99%+ efficiency to 5 micron

- Resources

WL Series Vacuum Filter Datasheet Inlet Vacuum Filters Maintenance Manual - Videos

Rent product

Interested in renting Solberg - WL Series Vacuum Filters? Please fill in the form below and we will get back to you in the shortest time.

{formbuilder:10226}