Your Cart is Empty

Rogers Machinery Articles & Case Studies

Rogers Machinery News is your place for informative, educational articles and case studies about air compressors, pumps, blowers & vacuum systems. Our goal is to provide useful information that will help you make informed product decisions – all to keep your facilities running efficiently with maximum uptime.

88 news articles

Why Oil-Free Compressed Air?

Compressed air users are becoming increasingly intolerant of contamination in their systems, whether it's in a patient’s lungs, food and beverage products, pharmaceuticals, or semiconductors. Eliminating the risk of contaminated end product, saving money in energy use, and maintenance are only a few of the benefits.

Liquids and Vacuum - Considerations & Best Practices

Vacuum systems play a critical role in a wide range of industrial applications, particularly where liquids are involved. Understanding how liquids behave under vacuum and how to optimize system performance is essential for efficiency, safety, and reliability. This article explores key considerations and best practices for working with liquids in vacuum environments.

Written by Jackson Redline

Pacific Northwest Winery Integrates Compressed Air System for Sustainable Wine Production

Compressed air is used throughout the winemaking process, though its uses can vary based on how each winery operates. One new winery in Walla Walla, Washington State’s wine-making hotbed, chose Rogers as their compressed air partner from the beginning to provide quality compressed air, low-maintenance equipment, and reliable service.

CNC Machining Company Relies on Rogers VFD Compressed Air System to Meet Expanding Production Demands

A CNC machining company utilizes compressed air to manufacture precision parts in the hundreds of thousands. In this case study, read how one CNC machining company relies on oil-lubricated compressed air and VFD technology to save on energy without compromising quality.

Estimated read time: 5 minutes

FS-Elliott Case Study: Steel Manufacturing

This case study exemplifies the power of innovation and expert collaboration in the steel industry. By modernizing its compressed air system, the facility enhanced production capacity and operational reliability while setting a new benchmark for sustainable steel production.

*This case study has been republished from FS-Elliott.

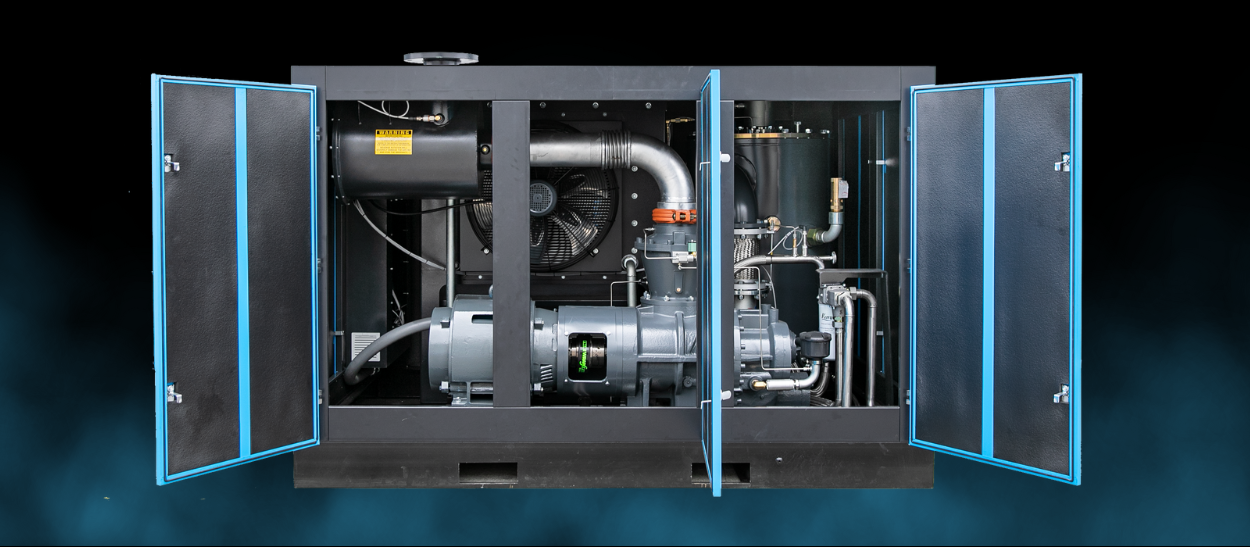

What is a Compressed Air System?

Compressed air systems require many components to run smoothly. In order to get the most out of your compressor and avoid costly air quality issues, you’ll need more than just a compressor in your system to run your facility. In this article, we will break down each component so you know exactly what your system needs. To learn more about compressed air in general, start with these articles.

Estimate read time: 6 minutes

Liquid Ring Vacuum Pump Dos and Don'ts

Liquid ring vacuum pump systems are very versatile and simple in nature. In this article, we discuss the components of a liquid ring vacuum pump, water usage & recirculation options, and best practices when operating this equipment.

Written by Jackson Redline, Engineered System Solutions Project Manager, Rogers Machinery

Estimated read time: 7 minutes

Parker Case Study: Cheese Production and Packaging

A company specializing in producing and packaging cheese products in the Northeastern United States started with humble beginnings, but has since grown tremendously and tripled the size of their cheese processing plant. Read how Parker helped source the right nitrogen generator for the plant.

A Guide to Selecting the Right Vacuum Pump for Your Application

This article will cover everything you need to know about choosing the best vacuum pump for your facility and application. We discuss some of the applications best suited for an oil-lubricated vs. oil-free vacuum pump, when you would want to control your system with a variable speed drive, and break down the top 6 situations a fixed speed drive for an oil-lubricated vacuum pump is best.

Estimated read time: 8 minutes

Compressed Air Piping Best Practices: Materials, Installation, and Maintenance

Compressed air piping is a vital component of any compressed air system. Whether you’re delivering air to food packaging lines or providing medical air for hospitals, piping matters. This article will discuss piping type, installation best practices, and proper maintenance.

Estimated read time: 6 minutes