Your Cart is Empty

Rogers Machinery Articles & Case Studies

Rogers Machinery News is your place for informative, educational articles and case studies about air compressors, pumps, blowers & vacuum systems. Our goal is to provide useful information that will help you make informed product decisions – all to keep your facilities running efficiently with maximum uptime.

88 news articles

8 Ways to Increase the Energy Efficiency of your Compressed Air System

Compressed air is essential for many industrial applications. However, it is expensive to produce. The total cost of ownership should be a factor when considering a compressed air system. Here are eight ways to increase the efficiency of your compressed air system.

Estimated read time: 7 minutes

Benefits of Air System Audits: What, When & How

A detailed compressed air energy audit examines the function and energy performance of a compressed air system with data collection as a core feature. Energy audits with data logging are a proven and powerful tool to solve complex problems and save energy, with positive results directly affecting the bottom line.

Written by John Molnar, P.E.

Implementing Vacuum System Innovations in the Real World: How Installation Location & Weather Affect Performance and System Design

High and low atmospheric pressures affect vacuum systems. But how much? In this article, vacuum expert Bryan A. Jensen covers how weather systems on our planet affect vacuum systems and how each type of vacuum usage — utility vacuum or process vacuum — responds to barometric changes in our atmosphere.

Winery Doubles Production with Nitrogen Generation Upgrades

Winemaking is big business. When Oregon-based winery NW Wine Company was looking to double their bottling production, they turned to Rogers for a solution that would power a much larger operation.

This case study is written in conjunction with NW Wine Company.

Organic Valley Keeping Local

In replacing the antiquated vacuum equipment with an energy efficient whole system solution, Organic Valley was able to save approximately 32,000 kWHrs and 16,000 gallons of water usage per year.

Engineering Laboratory Switches To A Reliable Compressed Air Supplier

After becoming frustrated with unreliable air compressors, poor support, and low-quality compressed air, Schweitzer Engineering Laboratories decided to rely on Rogers for all their compressed air needs.

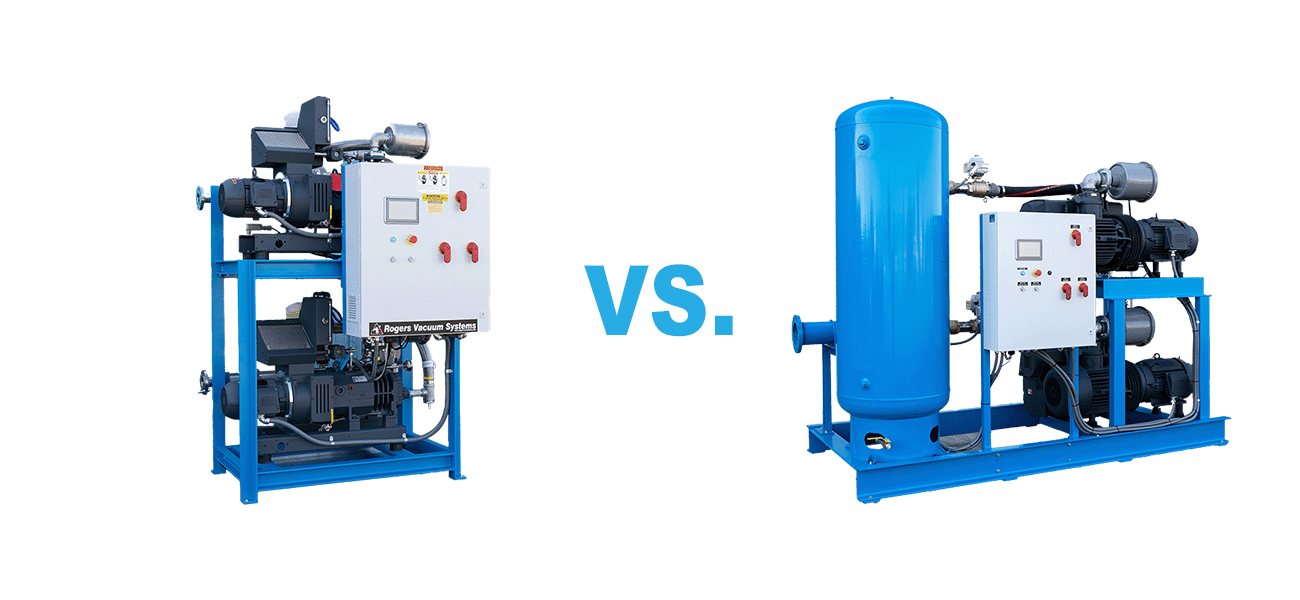

Vacuum Receivers: Full of Vacuum or Full of Myth?

In this article, we’ll discuss some of the uses for receiver tanks for positive pressure systems where the pressure inside the system is greater than atmospheric pressure, and the uses, or lack thereof of, receiver tanks in vacuum systems where the system pressure is less than atmospheric pressure.

In the Spirit of Improvement: Nation's Oldest Distiller Takes Practical Approach to Compressed Air System Upgrade

Laird & Company has been pioneering and perfecting Applejack brandy for 325 years. Laird & Company produces eight expressions of their iconic apple distillate, as well as a ready-to drink cocktail. In particular, their internationally known “Applejack” has earned the reputation as a quality product produced by a quality company using quality equipment to do so. In the interest of supporting facility uptime and Laird & Company’s personnel productivity, it was time for an upgrade.

Vacuum Thermodynamics in Our Freeze-Dried Universe

Freeze dry systems are some of the more thermodynamically active vacuum applications around, with operating pressure requirements firmly categorized in the “medium vacuum” realm. The lessons learned from the principles and subsystems in play can and should be applied broadly; to your own industrial vacuum system whether freeze-drying is your game or not; and, just maybe, in appreciation of the happenstance of our own humanity.

Written by: Bryan A. Jensen

Process Vacuum Applications & Oil-Free Technology

In this article, we dive into the differences between utility and process vacuum, measurement guidelines, and specifying vacuum systems to process applications for maximum system efficiency.

Written by: Bryan A. Jensen