Your Cart is Empty

Rogers Machinery Articles & Case Studies

Rogers Machinery News is your place for informative, educational articles and case studies about air compressors, pumps, blowers & vacuum systems. Our goal is to provide useful information that will help you make informed product decisions – all to keep your facilities running efficiently with maximum uptime.

88 news articles

Chocolate and Confectionery Pumps

Chocolate pumping has exacting specifications for temperature and sanitary conditions. This article and video introduce Viking Pump’s new chocolate pump.

Pumps for Ammonia Refrigerant Applications

Pumping Ammonia Refrigerant has certain inherent safety precautions due to the elevated pressure required to store it in a liquid state. This article and video show how to select the right pump for your ammonia processing application.

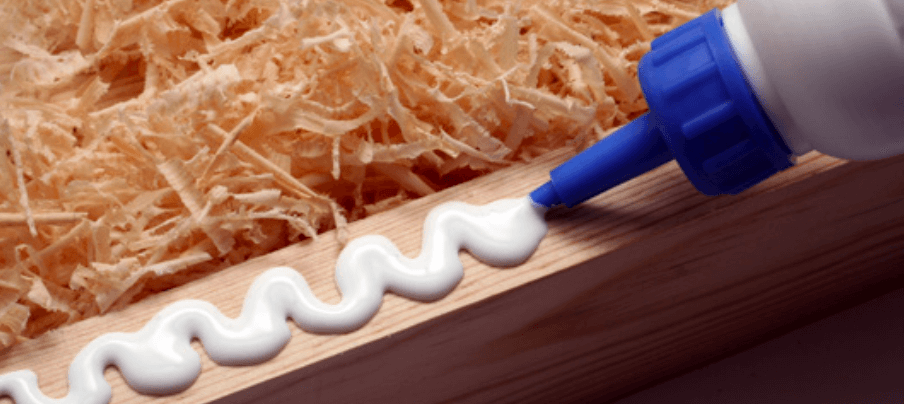

Adhesives Pumps

This article and video explain the requirements and suggested Viking Pump models for Adhesives Pumping applications

Pumps for Alcohol Applications

Pumping Alcohol is challenging due to the potential chemical attack on the pump body, gears, bushings and elastomers. This article and video shows how to match the specific alcohol being processed with the pump construction type that will offer the greatest chemical resistance.

Excessive Vacuum Pump Rebuilds Lead to a Better Vacuum System Solution

Learn how a recent customer saved over 110,000 kwh, $48,000 in repair costs and 150 manpower hours annually when a Rogers Sales Engineer noticed excessive repairs and recommended a better Vacuum System Solution.

A Midwest Potato Processor Expands to the Pacific Northwest

A major potato processor based in the Midwest was looking to expand in the Pacific Northwest. They came to Rogers Machinery because they have successfully partnered with Rogers Machinery and Viking Pump in the past.

Nine Reasons To Consider On-Site Nitrogen Generation

This article examines the three traditional gas supply methods and reasons why plant managers should consider using an on-site nitrogen generator as an alternative.

Entekra Expands to a New Production Facility

Entekra had plans to build a new production facility in Modesto, CA and needed to have an energy efficient and reliable compressed air system for the manufacturing process. Rogers Machinery was there to help and provided support, even after the sale.

A Local Hospital Consolidates Air System to Lower Costs and Improve Reliability

A local hospital in Utah needed help upgrading their air systems to one centralized system. Rogers Machinery was there to lower costs, increase reliability, simplify the overall system, and meet the NFPA-99 requirements.

J.M. Huber Improves Efficiency and Avoids Downtime

When the J.M. Huber Engineered Materials plant in Fairmount, GA needed service and repairs on its equipment, Rogers Machinery was there to help. When provided with the proper service and maintenance this plant was able to reduce 10 pounds of pressure from their system which yielded an annual energy savings of $24,000.